Table of Contents

The key points for the daily maintenance of brinell hardness testers include the following aspects:

First, cleaning and protection

- Regularly wipe the outer casing of the hardness tester with a clean and soft cloth to remove dust and stains.

- For example, wipe the casing with a dry cloth after each use to prevent dust from entering the interior of the instrument.

- Ensure that the hardness tester is placed in a dry, clean, vibration-free, and non-corrosive gas environment.

- For instance, avoid placing it near chemical reagents or in places with high humidity.

Second, maintenance of measurement components

- Regularly check whether the indenter is worn, damaged, or rusted.

- If the indenter is worn, it should be replaced promptly to ensure the accuracy of measurements.

- For example, after long-term use, the indenter may show tiny wear marks, and then an inspection is necessary.

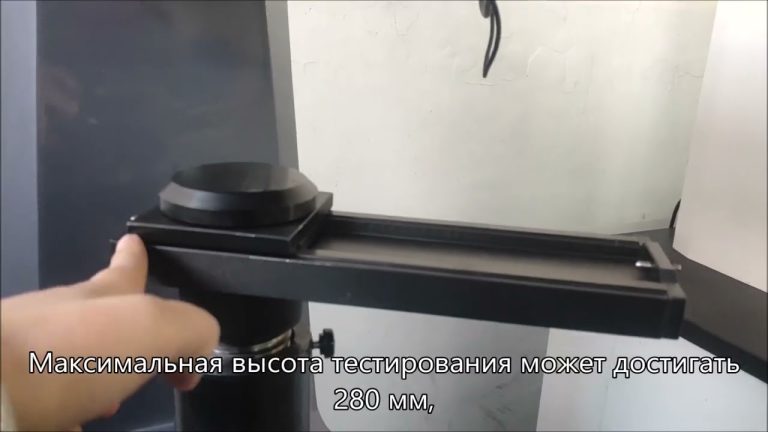

- Keep the measurement table clean and flat to prevent debris from affecting the measurement results.

- Regularly clean the debris and stains on the measurement table.

Third, maintenance of the transmission mechanism

1.Check the lubrication of transmission components such as lead screws and guide rails, and add an appropriate amount of lubricating oil in a timely manner.

1.For example, check the lubrication of the lead screw once every six months and add the appropriate lubricating oil.

2.Ensure that the transmission components move flexibly without jamming or abnormal resistance.

1.If the movement is not smooth, identify the cause and handle it promptly.

Fourth, inspection of the electrical system

1.Regularly check whether the power cord is damaged or aged.

1.For example, check the power cord once a year to prevent safety hazards such as electric leakage.

2.Confirm that the electrical connections of the instrument are firm and reliable without loosening.

Fifth, accuracy verification

1.Use standard hardness blocks to verify the accuracy of the hardness tester according to the prescribed cycle.

1.It is usually recommended to conduct the verification once every six months.

2.During the verification process, if a significant deviation in the measurement result is found, adjustments or repairs should be made in a timely manner.

Sixth, data recording and management

1.Record the usage situation each time, including the measured sample, measurement result, and usage time, etc. – This helps to track the usage of the instrument and identify potential problems.

2.Keep the relevant verification and maintenance records properly for future reference and review.