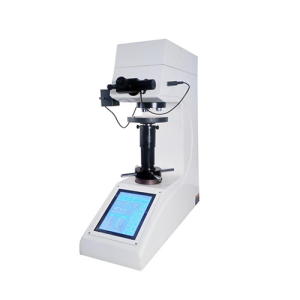

HBS-3000AET Touch Screen Digital Automatic Turret Brinell Hardness Tester

The HBS-3000AET Touch Screen Digital Brinell Hardness Tester features an 8-inch touch screen and a high-speed ARM processor, providing intuitive display, user-friendly human-machine interaction, and simple operation. It operates at high calculation speeds, offers extensive database storage, automatic data correction, and provides data trend line reports.

Product Overview

The HBS-3000AET Touch Screen Digital brinell hardness tester features an 8-inch touch screen and a high-speed ARM processor, providing intuitive display, user-friendly human-machine interaction, and simple operation. It operates at high calculation speeds, offers extensive database storage, automatic data correction, and provides data trend line reports.

Product Features

- The body is crafted from high-quality cast iron, single-cast, and treated with automotive paint for an aesthetically pleasing appearance.

- Equipped with an automatic turret function, enabling automatic switching between the indenter and lens for added convenience.

- Incorporates built-in hardness conversion scales for automatic unit conversion across all hardness scales.

- Electronically closed-loop controls are used to apply the test force, achieving fully automated loading, holding, and unloading operations.

- Features high-definition optical dual objectives, capable of measuring indentations under different standard test forces and diameters.

- Allows for setting the maximum and minimum hardness values; emitting an alarm sound when the test value exceeds the set range.

- Offers software hardness value correction, enabling direct correction of hardness values within a certain range.

- Provides a database function that automatically groups and saves test data, capable of storing over 2000 data points.

- Includes hardness value curve display functionality, visually demonstrating changes in hardness values.

- Equipped with a printer and supports data output through RS232 and USB (optional) interfaces.

- Optional accessories include CCD image processing systems or video measurement devices.

- Accuracy compliant with GB/T231.2, ISO 6506-2, and ASTM E10 standards.

Applications

- Used for determining the Brinell hardness of ferrous metals, non-ferrous metals, and bearing alloy materials.

- Applicable to hard alloys, carburized steels, quenched and tempered steels, surface hardened steels, hardened cast iron, aluminum alloys, copper alloys, malleable castings, mild steel, tempered steel, annealed steel, and bearing steel.

Technical Parameter

|

Model |

HBS-3000AET |

| Measuring Range |

5-650HBW |

| Test Force |

612.9N,980.7N,1225.9N,1838.8N,2451.8N,4903.5N,7355.3N,9807N,14710.5N,29421N (62.5kgf,100kgf,125kgf,187.5kgf,250kgf,500kgf,750kgf,1000kgf,1500kgf,3000kgf) |

|

Add The Way |

Electricity and charge |

|

Toward The Way |

Automatic tower |

| Test Method |

Automatic surveying and mapping |

| Maximum Height Is Allowed For The Specimen |

260mm |

|

Head Center To Machine Wall Distance |

150mm |

|

Vector Magnification |

1X,2X |

|

Total Magnification |

20X,40X |

|

Hardness Resolution |

0.1HBW |

| Source |

AC 220V,50Hz |

| Outline Dimension |

700*268*930mm |

| Weight |

200kg |

Standard Configuration Of Accessories

|

Daping Workbench |

One piece | Type V Workbench | One piece |

|

φ 2.5,φ 5,φ 10mm Carbented Ball Head |

One of Each | φ 2.5,φ 5,φ 10mm Hard Alloy Steel Ball |

One of Each |

|

Standard Brinell Hardness Block |

Two pieces | 20X Digital Graphic Microocular |

One piece |

| Printer | One piece |

|

The above is the standard configuration, and the actual configuration is subject to the customized requirements.