Table of Contents

Benefits of hardness testing for Polymers

Hardness testing is a crucial process in the manufacturing and quality control of polymers. Polymers are widely used in various industries, including automotive, aerospace, electronics, and medical devices. The hardness of a polymer material can affect its performance, durability, and overall quality. Therefore, it is essential to conduct hardness testing to ensure that the polymer meets the required specifications and standards.

One of the main benefits of hardness testing for polymers is that it provides valuable information about the material’s mechanical properties. Hardness is a measure of a material’s resistance to indentation or scratching, and it can indicate the material’s strength, toughness, and wear resistance. By measuring the hardness of a polymer, manufacturers can assess its suitability for specific applications and determine if it meets the desired performance requirements.

Another benefit of hardness testing for polymers is that it helps identify any defects or inconsistencies in the material. Variations in hardness across a polymer sample can indicate uneven distribution of additives, improper curing or processing conditions, or other manufacturing defects. By detecting these issues early on, manufacturers can take corrective actions to improve the quality and consistency of their products.

Hardness testing also plays a crucial role in ensuring the reliability and safety of polymer components. In industries such as automotive and aerospace, where polymers are used in critical applications, it is essential to verify that the material can withstand the required loads and environmental conditions. Hardness testing can help determine if a polymer component is strong enough to resist impact, abrasion, or other mechanical stresses, thus reducing the risk of failure or premature wear.

Furthermore, hardness testing can be used to compare different polymer materials and formulations. By measuring the hardness of various samples, manufacturers can evaluate the performance of different polymers and select the most suitable material for a specific application. This can help optimize the design and production process, leading to cost savings and improved product quality.

In addition to these benefits, hardness testing of polymers can also help in research and development efforts. By studying the relationship between hardness and other mechanical properties, researchers can gain insights into the structure and behavior of polymer materials. This knowledge can be used to develop new materials with enhanced properties, such as increased strength, flexibility, or chemical resistance.

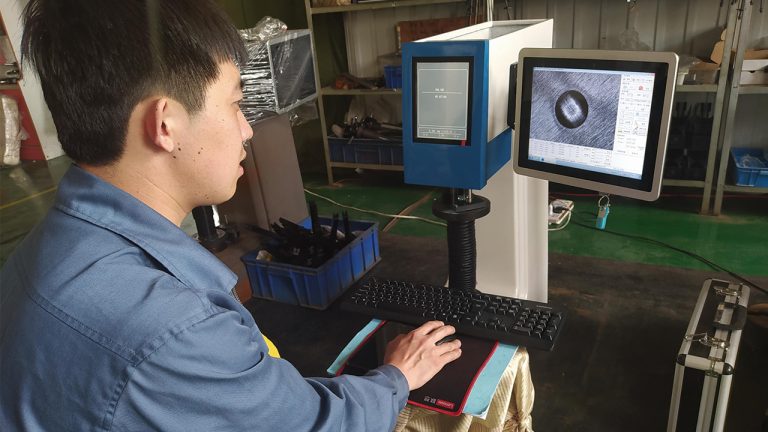

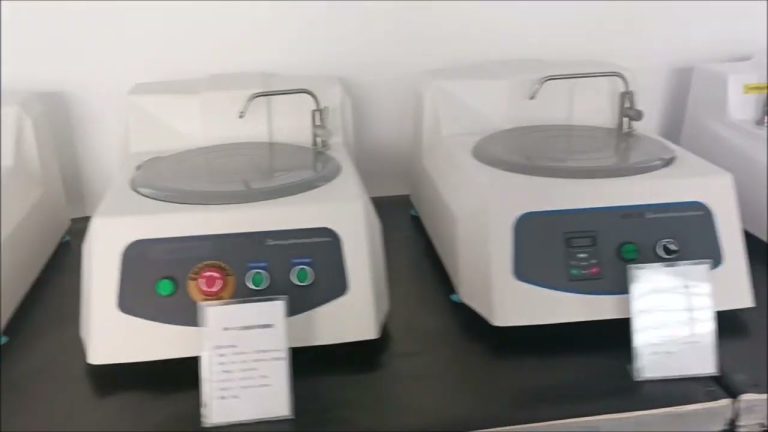

When it comes to hardness testing of polymers, China is known for its expertise and cost-effective solutions. Chinese suppliers offer a wide range of hardness testing equipment and services, including portable hardness testers, benchtop instruments, and automated testing systems. These suppliers have extensive experience in the polymer industry and can provide customized solutions to meet specific testing requirements.

In conclusion, hardness testing is a critical process for ensuring the quality, reliability, and performance of polymer materials. By measuring the hardness of polymers, manufacturers can assess their mechanical properties, detect defects, compare different materials, and support research and development efforts. With the expertise and affordability of Chinese suppliers, hardness testing of polymers has become more accessible and efficient than ever before.

How to Choose the Best Supplier for Hardness Testing Equipment in China

When it comes to hardness testing of polymers, finding the right supplier for equipment is crucial. China has become a hub for manufacturing and supplying hardness testing equipment, offering a wide range of options at competitive prices. However, with so many suppliers to choose from, it can be overwhelming to determine which one is the best fit for your needs. In this article, we will discuss how to choose the best supplier for hardness testing equipment in China.

One of the first things to consider when selecting a supplier is the quality of their products. It is essential to ensure that the equipment you are purchasing is of high quality and will provide accurate and reliable results. Look for suppliers that have a good reputation for producing durable and precise hardness testing equipment. Reading customer reviews and testimonials can give you insight into the quality of the products offered by a particular supplier.

In addition to quality, it is also important to consider the price of the equipment. While it is tempting to opt for the cheapest supplier, it is essential to remember that quality should not be compromised for cost. Look for suppliers that offer competitive prices without sacrificing the quality of their products. Comparing prices from different suppliers can help you find the best deal without compromising on the quality of the equipment.

Another factor to consider when choosing a supplier is their customer service and support. A reliable supplier should be able to provide assistance with installation, maintenance, and troubleshooting of the equipment. Look for suppliers that offer excellent customer service and have a dedicated support team to address any issues or concerns you may have. Good communication with the supplier is essential to ensure a smooth purchasing process and ongoing support for your equipment.

When selecting a supplier for hardness testing equipment in China, it is also important to consider their experience and expertise in the industry. Look for suppliers that have a proven track record of delivering high-quality products and have a deep understanding of the requirements for hardness testing of polymers. Experienced suppliers are more likely to provide reliable and accurate equipment that meets your specific needs.

Furthermore, it is essential to consider the range of products offered by the supplier. Look for suppliers that offer a variety of hardness testing equipment to choose from, including different models and specifications to suit your requirements. A supplier with a diverse product range can provide you with more options and flexibility in selecting the right equipment for your needs.

In conclusion, choosing the best supplier for hardness testing equipment in China requires careful consideration of factors such as quality, price, customer service, experience, and product range. By taking the time to research and compare different suppliers, you can find a reliable partner that offers high-quality equipment at competitive prices. Remember to prioritize quality and reliability when selecting a supplier to ensure that you get the best value for your investment in hardness testing equipment.