Choosing the Right Tablet hardness tester Supplier for Your Manufacturing Needs

Choosing the Right Tablet Hardness Tester Supplier for Your Manufacturing Needs

When it comes to manufacturing tablets, ensuring their quality and durability is of utmost importance. Tablet hardness testing is a crucial step in the manufacturing process, as it determines the strength and integrity of the tablets. To perform this test accurately, you need a reliable tablet hardness tester. But with so many suppliers in the market, how do you choose the right one for your manufacturing needs? In this article, we will discuss the key factors to consider when selecting a tablet hardness tester supplier.

First and foremost, you need to assess the reputation and experience of the supplier. Look for a supplier that has been in the industry for a significant amount of time and has a proven track record of delivering high-quality products. A reputable supplier will have a strong customer base and positive reviews from satisfied clients. Additionally, they should have a good understanding of the tablet manufacturing process and be able to provide expert advice and support.

Next, consider the range of tablet hardness testers offered by the supplier. Different manufacturing processes require different types of testers. Some suppliers may specialize in specific types of testers, while others may offer a wide variety to cater to different needs. It is important to choose a supplier that can provide you with the right type of tester for your specific requirements. This will ensure that you can accurately test the hardness of your tablets and make informed decisions about their quality.

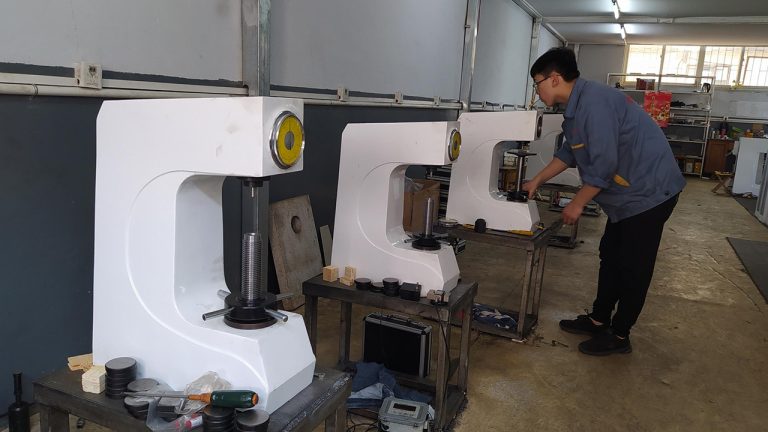

Another crucial factor to consider is the quality of the tablet hardness testers provided by the supplier. The accuracy and reliability of the testers are essential for obtaining accurate results. Look for suppliers that use high-quality materials and advanced technology in their testers. Additionally, check if the supplier follows strict quality control measures during the manufacturing process. This will give you confidence in the performance and longevity of the testers.

In addition to the quality of the testers, you should also consider the after-sales support provided by the supplier. Tablet hardness testers are complex instruments that may require maintenance and repairs over time. A reliable supplier should offer comprehensive after-sales support, including technical assistance, spare parts availability, and repair services. This will ensure that your testers remain in optimal condition and continue to deliver accurate results.

Furthermore, consider the pricing and overall value offered by the supplier. While it is important to find a supplier that offers competitive prices, it is equally important to assess the overall value of their products and services. Look for suppliers that offer a balance between affordability and quality. Consider factors such as warranty periods, additional features, and customer support when evaluating the value proposition of a supplier.

Lastly, don’t forget to consider the supplier’s location and shipping capabilities. If you are located in a different country or region, it is important to choose a supplier that can efficiently ship the tablet hardness testers to your location. Look for suppliers with a reliable logistics network and experience in international shipping.

In conclusion, choosing the right tablet hardness tester supplier for your manufacturing needs requires careful consideration of various factors. Assess the reputation, experience, and range of testers offered by the supplier. Ensure that they provide high-quality products and comprehensive after-sales support. Evaluate the pricing and overall value offered by the supplier. Finally, consider their location and shipping capabilities. By taking these factors into account, you can make an informed decision and find a supplier that meets your tablet hardness testing requirements.