Understanding the Importance of hardness testing in Engineering

Hardness testing is a critical aspect of engineering that plays a crucial role in ensuring the quality and reliability of materials used in various applications. It involves measuring the resistance of a material to indentation or scratching, which provides valuable information about its mechanical properties. Understanding the importance of hardness testing in engineering is essential for ensuring the safety and performance of products and structures.

One of the key reasons why hardness testing is important in engineering is its ability to assess the strength and durability of materials. By measuring the hardness of a material, engineers can determine its ability to withstand external forces and loads, which is essential for designing components and structures that can perform under challenging conditions. Hardness testing helps engineers identify weak spots in materials that could lead to failure, allowing them to make informed decisions about material selection and design.

Another important aspect of hardness testing in engineering is its role in quality control and assurance. By conducting hardness tests on materials during the manufacturing process, engineers can ensure that they meet the required specifications and standards. This helps prevent defects and inconsistencies in materials, which can compromise the performance and safety of products. Hardness testing is also used to verify the authenticity of materials and detect any potential issues that could affect their performance.

In addition to strength and quality control, hardness testing is also essential for evaluating the wear resistance of materials. Wear resistance is a critical factor in many engineering applications, especially in industries such as automotive, aerospace, and manufacturing. By measuring the hardness of materials, engineers can predict their ability to resist wear and abrasion, which is crucial for determining their lifespan and performance in real-world conditions. Hardness testing helps engineers select materials that can withstand wear and friction, reducing maintenance costs and improving the longevity of products.

Furthermore, hardness testing is important for research and development in engineering. By studying the hardness of materials, engineers can gain valuable insights into their properties and behavior under different conditions. This information is essential for developing new materials and improving existing ones, leading to innovations in various industries. Hardness testing allows engineers to optimize material performance and design products that meet the evolving needs of the market.

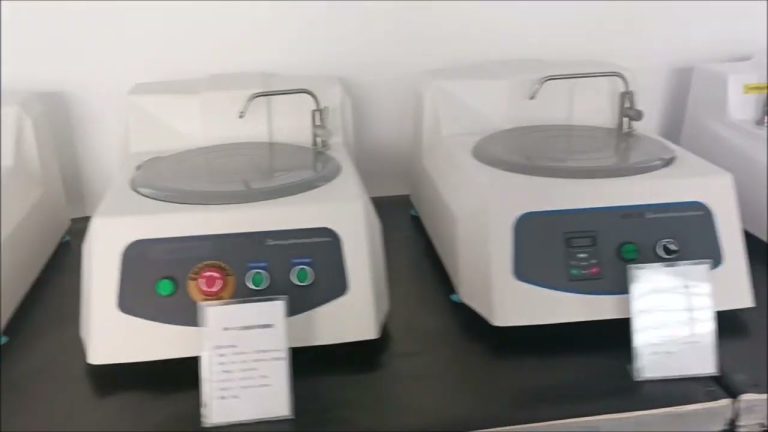

When it comes to hardness testing in engineering, Chinese suppliers are known for their high-quality products and services. Chinese suppliers offer a wide range of hardness testing equipment and services that meet the needs of various industries. With advanced technology and expertise in the field, Chinese suppliers provide reliable and accurate hardness testing solutions that help engineers ensure the quality and performance of their products.

In conclusion, hardness testing plays a crucial role in engineering by assessing the strength, quality, wear resistance, and research and development of materials. Understanding the importance of hardness testing is essential for ensuring the safety, reliability, and performance of products and structures. Chinese suppliers are among the best in the world when it comes to hardness testing equipment and services, offering advanced solutions that meet the needs of the engineering industry. By investing in hardness testing, engineers can make informed decisions about material selection, design, and quality control, leading to improved products and innovations in various industries.