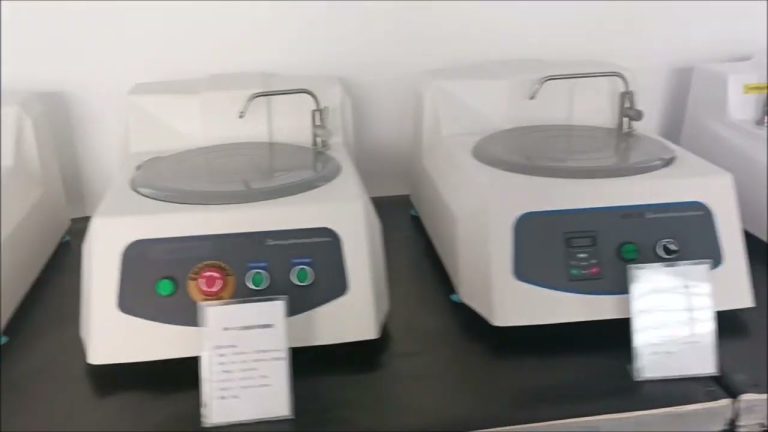

Benefits of Using hardness testing Equipment for Quality Control in Manufacturing Industries

Hardness testing equipment plays a crucial role in quality control within manufacturing industries. Ensuring that materials used in production meet the required hardness standards is essential for producing high-quality products that meet customer expectations. In China, there are many high-quality exporters of hardness testing equipment that cater to the needs of various industries.

One of the key benefits of using hardness testing equipment is the ability to accurately measure the hardness of materials. Hardness is a critical property that determines the material’s resistance to deformation, wear, and scratching. By using hardness testing equipment, manufacturers can ensure that the materials they are using meet the required hardness specifications for a particular application.

Another benefit of using hardness testing equipment is the ability to identify any inconsistencies or defects in the material. By conducting hardness tests on samples of materials, manufacturers can detect any variations in hardness that may indicate a problem with the material’s composition or processing. This early detection of defects can help prevent costly production errors and ensure that only high-quality materials are used in the manufacturing process.

Furthermore, hardness testing equipment allows manufacturers to monitor the quality of materials throughout the production process. By conducting regular hardness tests on materials at different stages of production, manufacturers can ensure that the materials maintain the required hardness levels and meet the quality standards set for the final product. This proactive approach to quality control helps prevent defects and ensures that the finished products meet the desired specifications.

In addition to ensuring the quality of materials, hardness testing equipment also helps manufacturers improve the overall efficiency of their production processes. By quickly and accurately measuring the hardness of materials, manufacturers can make informed decisions about the processing parameters and optimize the production process for maximum efficiency. This can lead to cost savings, reduced waste, and improved productivity, ultimately benefiting the bottom line of the manufacturing industry.

Moreover, hardness testing equipment is essential for maintaining compliance with industry standards and regulations. Many industries have specific hardness requirements that must be met to ensure the safety and reliability of the products. By using hardness testing equipment, manufacturers can demonstrate compliance with these standards and provide assurance to customers that their products meet the necessary quality requirements.

Overall, hardness testing equipment is a valuable tool for quality control in manufacturing industries. By accurately measuring the hardness of materials, identifying defects, monitoring quality throughout the production process, improving efficiency, and ensuring compliance with industry standards, manufacturers can produce high-quality products that meet customer expectations. In China, there are many high-quality exporters of hardness testing equipment that provide reliable and accurate solutions for the diverse needs of manufacturing industries. Investing in quality hardness testing equipment is essential for maintaining the competitiveness and reputation of manufacturing companies in today’s global market.