Table of Contents

Benefits of Using Barcol hardness tester in Various Industries

Barcol hardness testers are essential tools used in various industries to measure the hardness of materials. These testers are widely used in industries such as automotive, aerospace, construction, and manufacturing. The Barcol hardness tester is a portable device that provides accurate and reliable measurements of the hardness of materials.

One of the key benefits of using a Barcol hardness tester is its versatility. These testers can be used to measure the hardness of a wide range of materials, including plastics, composites, and metals. This makes them an essential tool for industries that work with a variety of materials.

In addition to their versatility, Barcol hardness testers are also easy to use. These testers are portable and can be used in the field or in a laboratory setting. They provide quick and accurate measurements, allowing for efficient testing of materials.

Another benefit of using a Barcol hardness tester is its durability. These testers are built to withstand harsh working conditions and are designed to last for years. This makes them a cost-effective investment for industries that require reliable hardness testing equipment.

Furthermore, Barcol hardness testers are customizable to meet the specific needs of different industries. China has become a hub for customization of Barcol hardness testers, with many factories offering tailor-made solutions for various industries.

Customization options for Barcol hardness testers include different probe sizes, calibration settings, and data recording capabilities. This allows industries to have a tester that meets their specific requirements and provides accurate and reliable measurements.

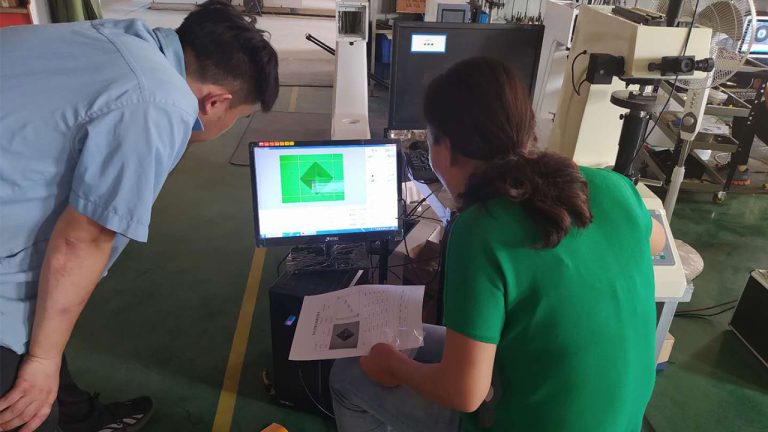

China has emerged as a leading manufacturer of Barcol hardness testers, with many factories offering high-quality products at competitive prices. These factories have the expertise and technology to produce customized testers that meet the needs of different industries.

In conclusion, the benefits of using a Barcol hardness tester in various industries are numerous. These testers are versatile, easy to use, durable, and customizable, making them an essential tool for industries that require accurate hardness measurements. China has become a leading manufacturer of Barcol hardness testers, offering customized solutions for different industries. Investing in a Barcol hardness tester from a China customization factory is a wise decision for industries looking for reliable and efficient hardness testing equipment.

How to Choose the Right Barcol Hardness Tester for Your Needs

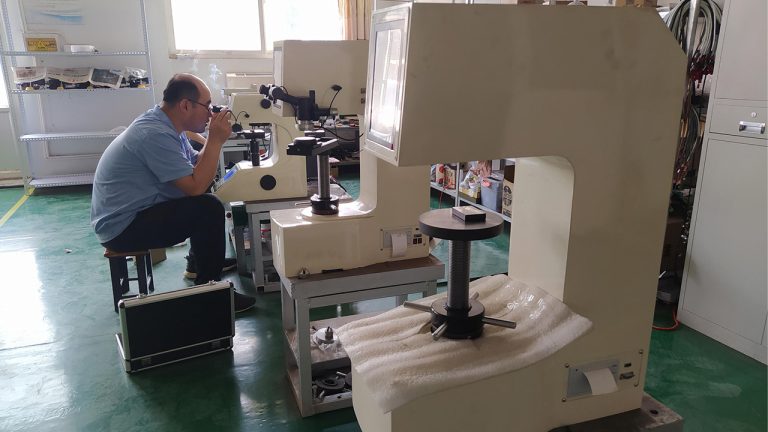

When it comes to choosing the right Barcol hardness tester for your needs, there are several factors to consider. Barcol hardness testers are used to measure the hardness of materials, particularly composite materials such as fiberglass, plastics, and aluminum. These testers are essential for ensuring the quality and durability of these materials in various industries, including aerospace, automotive, and construction.

One of the most important factors to consider when choosing a Barcol hardness tester is the type of material you will be testing. Different materials have different hardness levels, so it is crucial to select a tester that is suitable for the specific material you will be working with. For example, if you will be testing fiberglass, you will need a tester that is designed to measure the hardness of this particular material.

In addition to the type of material, you should also consider the size and shape of the samples you will be testing. Some Barcol hardness testers are designed for small, flat samples, while others are better suited for larger or irregularly shaped samples. It is essential to choose a tester that can accommodate the size and shape of the samples you will be working with to ensure accurate and reliable results.

Another important factor to consider when choosing a Barcol hardness tester is the accuracy and precision of the instrument. The accuracy of the tester will determine how reliable the results are, while the precision will determine how consistent the results are. It is crucial to choose a tester that offers both high accuracy and precision to ensure that you can trust the results it provides.

When selecting a Barcol hardness tester, it is also essential to consider the testing method and procedure. Some testers require manual operation, while others are automated and can provide results quickly and efficiently. The testing method and procedure will depend on your specific needs and preferences, so it is essential to choose a tester that aligns with your requirements.

In addition to the factors mentioned above, you should also consider the reputation and reliability of the manufacturer. Choosing a Barcol hardness tester from a reputable and reliable manufacturer will ensure that you are investing in a high-quality instrument that will provide accurate and consistent results. It is essential to research different manufacturers and read reviews from other customers to determine which one is the best fit for your needs.

In conclusion, choosing the right Barcol hardness tester for your needs requires careful consideration of several factors, including the type of material, size and shape of samples, accuracy and precision, testing method and procedure, and the reputation of the manufacturer. By taking the time to evaluate these factors and choose a tester that meets your specific requirements, you can ensure that you are investing in a high-quality instrument that will provide reliable results for your testing needs.

Top Features to Look for in a Barcol Hardness Tester from a China Customization Factory

When it comes to selecting a barcol hardness tester from a China customization factory, there are several key features that you should consider to ensure that you are getting the best product for your needs. Barcol hardness testers are used to measure the hardness of materials, particularly composite materials such as fiberglass, plastics, and other non-metallic materials. These testers are essential for quality control and ensuring that materials meet the necessary specifications for their intended use.

One of the most important features to look for in a barcol hardness tester is accuracy. The accuracy of the tester will determine how reliable the hardness readings are, which is crucial for ensuring the quality of the materials being tested. A high level of accuracy is essential for making informed decisions about the suitability of materials for specific applications. Look for a barcol hardness tester that has a high level of accuracy and is calibrated to industry standards.

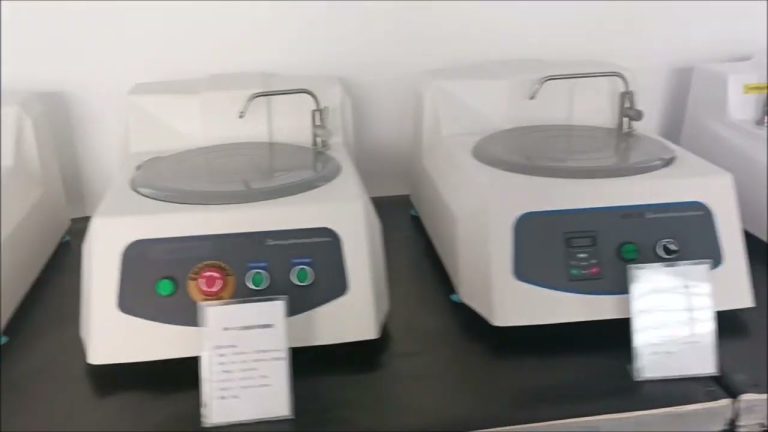

Another important feature to consider is the durability of the tester. Barcol hardness testers are often used in industrial settings where they may be subjected to harsh conditions and heavy use. A durable tester will be able to withstand these conditions and continue to provide accurate readings over time. Look for a tester that is made from high-quality materials and has a robust design that can withstand the rigors of industrial use.

Ease of use is also an important factor to consider when selecting a barcol hardness tester. A user-friendly tester will make it easier for operators to take accurate readings and interpret the results. Look for a tester that has a clear and intuitive interface, with easy-to-read displays and simple controls. Some testers may also come with additional features such as data logging capabilities or automatic calculations, which can further enhance usability.

In addition to accuracy, durability, and ease of use, it is also important to consider the customization options available from the China factory. Customization can allow you to tailor the tester to your specific needs and requirements, ensuring that it meets the unique demands of your application. Look for a factory that offers a range of customization options, such as different probe sizes, calibration settings, or additional features that can be added to the tester.

Finally, consider the reputation of the China customization factory when selecting a barcol hardness tester. A factory with a strong reputation for quality and reliability is more likely to provide a high-quality product that meets your expectations. Look for reviews and testimonials from other customers to gauge the factory’s reputation and ensure that you are getting the best possible product.

In conclusion, when selecting a barcol hardness tester from a China customization factory, it is important to consider a range of features to ensure that you are getting the best product for your needs. Look for a tester that offers high accuracy, durability, ease of use, customization options, and a strong reputation from the factory. By considering these factors, you can be confident that you are getting a high-quality barcol hardness tester that will meet your requirements and provide reliable hardness readings for your materials.