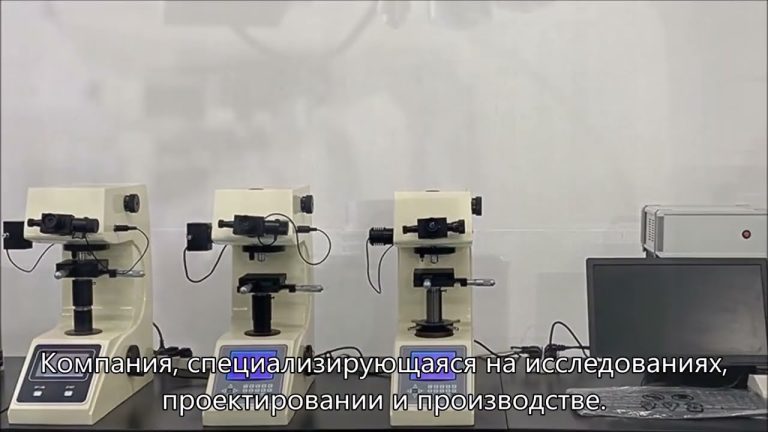

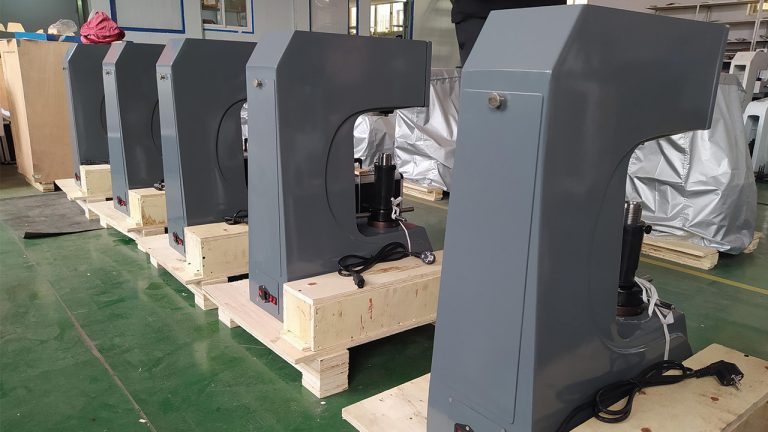

core hardness tester Chinese high quality affordable Professional manufacturer

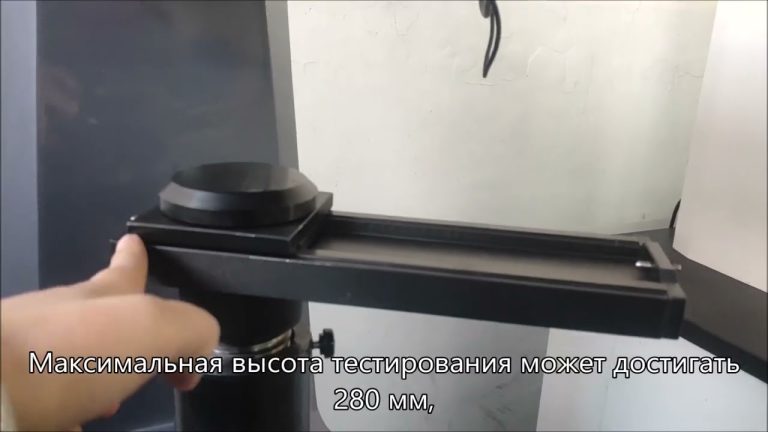

Benefits of Using a Core hardness tester in Quality Control Processes In the manufacturing industry, quality control is of utmost importance to ensure that products meet the required standards and specifications. One crucial aspect of quality control is testing the hardness of materials used in the production process. This is…