Table of Contents

Benefits of hardness testing for Graphite Products

Graphite is a versatile material that is widely used in various industries due to its unique properties such as high thermal conductivity, low coefficient of thermal expansion, and chemical inertness. However, the quality and performance of graphite products can vary depending on factors such as manufacturing process, raw materials used, and production techniques. To ensure the quality and reliability of graphite products, hardness testing is essential.

Hardness testing is a non-destructive method used to measure the resistance of a material to indentation or scratching. In the case of graphite products, hardness testing is crucial to determine the material’s strength, durability, and overall quality. By conducting hardness tests on graphite products, manufacturers can ensure that the products meet the required specifications and standards, thus guaranteeing their performance and longevity.

One of the main benefits of hardness testing for graphite products is quality control. By measuring the hardness of graphite products, manufacturers can identify any defects or inconsistencies in the material that may affect its performance. This allows manufacturers to take corrective actions to improve the quality of the products and prevent any potential issues that may arise during use.

In addition to quality control, hardness testing also helps manufacturers to optimize the production process. By analyzing the hardness data obtained from testing, manufacturers can identify areas for improvement in the manufacturing process, such as adjusting the temperature or pressure during production, selecting better raw materials, or implementing new production techniques. This can lead to increased efficiency, reduced production costs, and improved product quality.

Furthermore, hardness testing is essential for ensuring the reliability and safety of graphite products. By measuring the hardness of graphite products, manufacturers can determine their resistance to wear, abrasion, and impact, which are important factors in applications where the products are subjected to harsh conditions or high stress. This information allows manufacturers to design and produce graphite products that can withstand the demands of their intended use, thus ensuring the safety and reliability of the products.

Moreover, hardness testing is also important for quality assurance and certification purposes. Many industries, such as aerospace, automotive, and electronics, have strict quality standards and regulations that require manufacturers to conduct hardness testing on their products to ensure compliance. By performing hardness tests on graphite products, manufacturers can demonstrate that their products meet the required specifications and standards, thus gaining the trust and confidence of their customers and stakeholders.

In conclusion, hardness testing is a critical process for ensuring the quality, reliability, and performance of graphite products. By conducting hardness tests on graphite products, manufacturers can control the quality of their products, optimize the production process, ensure product reliability and safety, and meet quality standards and regulations. Therefore, hardness testing is an essential tool for manufacturers to produce high-quality graphite products that meet the demands of various industries and applications.

How to Choose a High-Grade Graphite Manufacturer in China

Graphite is a versatile material that is used in a wide range of industries, from electronics to aerospace. When it comes to choosing a high-grade graphite manufacturer in China, there are several factors to consider to ensure that you are getting the best quality product for your needs.

One of the most important factors to consider when choosing a graphite manufacturer is the hardness of the material. Hardness is a key indicator of the quality of graphite, as it can affect its performance and durability in various applications. To determine the hardness of graphite, manufacturers use a hardness test, which measures the material’s resistance to indentation.

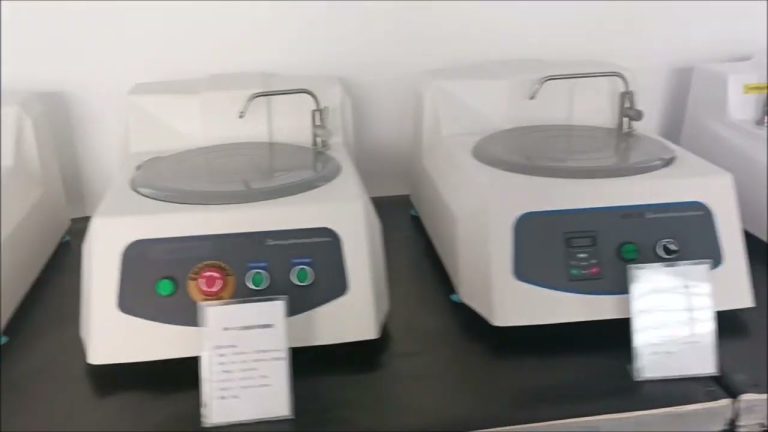

When looking for a high-grade graphite manufacturer in China, it is important to choose a company that uses reliable and accurate hardness testing methods. This will ensure that you are getting a product that meets your specifications and requirements. A reputable manufacturer will have the necessary equipment and expertise to perform hardness tests on their graphite products, providing you with the assurance that you are getting a high-quality material.

In addition to hardness testing, it is also important to consider the manufacturing process used by the graphite manufacturer. The quality of the manufacturing process can have a significant impact on the final product, so it is important to choose a manufacturer that uses advanced techniques and technologies to produce high-grade graphite.

Look for a manufacturer that has a proven track record of producing high-quality graphite products for a range of industries. This will give you confidence that they have the expertise and experience to meet your specific requirements and deliver a product that meets your expectations.

Another important factor to consider when choosing a high-grade graphite manufacturer in China is the company’s reputation and customer reviews. Look for a manufacturer that has a strong reputation for quality and reliability, as this will give you peace of mind that you are working with a reputable company.

Customer reviews can also provide valuable insights into the quality of a manufacturer’s products and services. Look for reviews from other customers who have worked with the manufacturer in the past, as this can give you a better understanding of what to expect when working with them.

When choosing a high-grade graphite manufacturer in China, it is important to consider all of these factors to ensure that you are getting the best quality product for your needs. By choosing a manufacturer that uses reliable hardness testing methods, has a strong reputation, and uses advanced manufacturing techniques, you can be confident that you are getting a high-grade graphite product that meets your specifications and requirements.