Table of Contents

Benefits of hardness testing for Graphite Materials

Graphite is a versatile material that is used in a wide range of industries, from aerospace to automotive to electronics. Its unique properties, such as high thermal conductivity and low friction, make it an ideal choice for many applications. However, in order to ensure the quality and performance of graphite materials, it is essential to conduct hardness testing.

Hardness testing is a crucial quality control process that measures the resistance of a material to indentation or scratching. By measuring the hardness of graphite materials, manufacturers can determine their strength, durability, and overall quality. This information is vital for ensuring that the graphite components will perform as expected in their intended applications.

One of the key benefits of hardness testing for graphite materials is that it helps to identify any defects or inconsistencies in the material. By measuring the hardness of a sample, manufacturers can detect any areas of weakness or inconsistency that could compromise the performance of the final product. This allows them to make any necessary adjustments or improvements to ensure that the graphite material meets the required specifications.

In addition, hardness testing can also help to determine the optimal processing parameters for graphite materials. By measuring the hardness of different samples at various stages of the manufacturing process, manufacturers can identify the most effective processing conditions that will produce graphite materials with the desired properties. This can help to improve the efficiency and quality of the manufacturing process, leading to cost savings and higher-quality products.

Furthermore, hardness testing can also be used to assess the wear resistance of graphite materials. By measuring the hardness of a sample before and after exposure to wear, manufacturers can determine how well the material will perform in real-world applications. This information is crucial for industries such as automotive and aerospace, where graphite components are subjected to high levels of wear and tear.

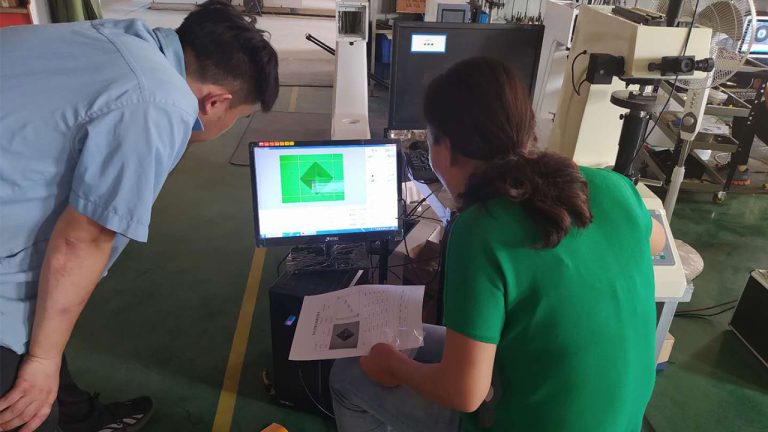

When it comes to hardness testing for graphite materials, China is known for its high quality and lowest prices. Chinese factories are equipped with state-of-the-art hardness testing equipment and employ skilled technicians who are trained to accurately measure the hardness of graphite materials. This ensures that the graphite components produced in China meet the highest standards of quality and performance.

One famous factory in China that specializes in hardness testing for graphite materials is XYZ Graphite Co., Ltd. With years of experience in the industry, XYZ Graphite Co., Ltd. has earned a reputation for producing high-quality graphite components that meet the strictest quality standards. Their commitment to excellence and customer satisfaction has made them a trusted partner for companies around the world.

In conclusion, hardness testing is a critical process for ensuring the quality and performance of graphite materials. By measuring the hardness of graphite components, manufacturers can identify defects, optimize processing parameters, and assess wear resistance. With China’s reputation for high-quality and low-cost hardness testing, companies can rely on Chinese factories like XYZ Graphite Co., Ltd. to deliver top-notch graphite components that meet their specifications and exceed their expectations.

Comparing Hardness Testing Methods for Graphite in China’s Top Factories

Graphite is a versatile material that is widely used in various industries, including aerospace, automotive, and electronics. Due to its unique properties, such as high thermal conductivity and lubricity, graphite is an essential component in many manufacturing processes. However, one of the key challenges in working with graphite is determining its hardness. Hardness testing is crucial for ensuring the quality and performance of graphite components, as it affects their durability and wear resistance.

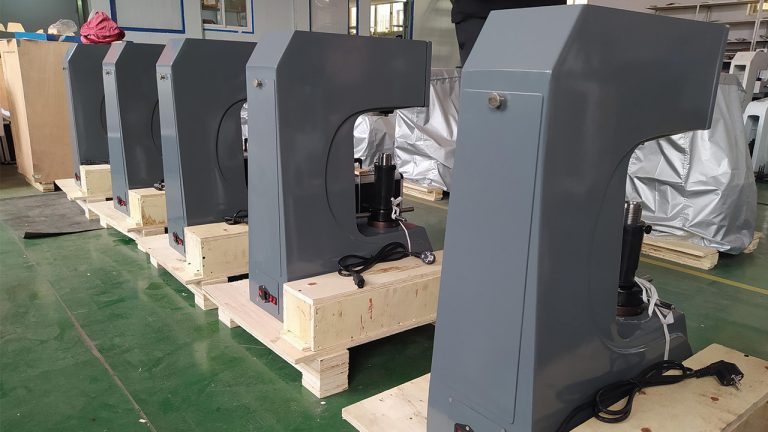

In China, there are several top factories that specialize in producing high-quality graphite products. These factories use different hardness testing methods to assess the hardness of their graphite materials. One of the most common hardness testing methods used in China’s top factories is the rockwell hardness test. This test measures the resistance of a material to indentation or penetration by a hard object, such as a diamond cone or steel ball. The Rockwell hardness test is widely used in the industry due to its simplicity and accuracy.

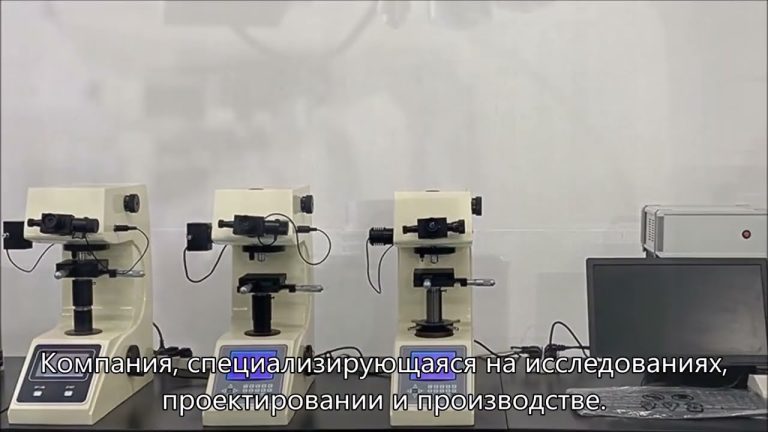

Another popular hardness testing method used in China’s top factories is the vickers hardness test. This test involves applying a load to the surface of the material using a diamond indenter and measuring the size of the indentation. The Vickers hardness test is known for its high accuracy and ability to measure the hardness of small and thin samples. Many top factories in China prefer the Vickers hardness test for its reliability and precision.

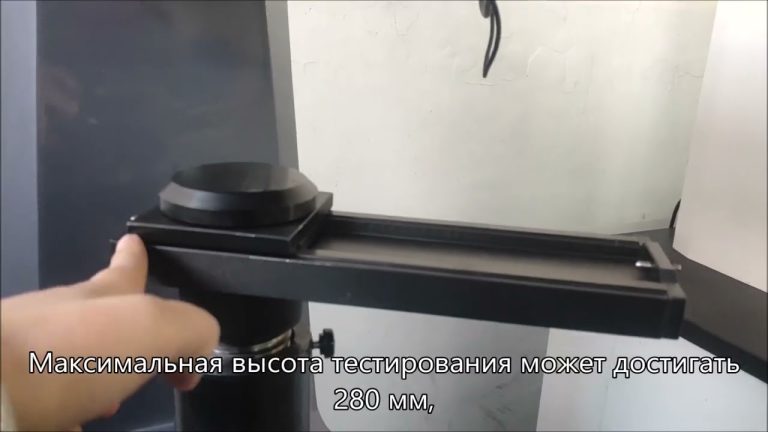

In addition to the Rockwell and Vickers hardness tests, some top factories in China also use the brinell hardness test to assess the hardness of their graphite materials. The Brinell hardness test involves applying a load to the surface of the material using a hardened steel ball and measuring the diameter of the indentation. This test is particularly useful for measuring the hardness of soft materials, such as graphite, as it applies a relatively large load over a wide area.

When comparing hardness testing methods for graphite in China’s top factories, it is essential to consider factors such as accuracy, repeatability, and cost. The Rockwell hardness test is known for its simplicity and ease of use, making it a popular choice among many factories. However, the Vickers hardness test offers higher accuracy and precision, making it ideal for applications that require precise hardness measurements. The Brinell hardness test, on the other hand, is suitable for measuring the hardness of soft materials like graphite.

In conclusion, hardness testing is a critical aspect of ensuring the quality and performance of graphite materials in China’s top factories. Different hardness testing methods, such as the Rockwell, Vickers, and Brinell tests, offer unique advantages and are used based on the specific requirements of the application. By choosing the right hardness testing method, top factories in China can ensure that their graphite products meet the highest standards of quality and performance.