Table of Contents

Benefits of Conducting hardness tests on Graphite Products

Graphite is a versatile material that is used in a wide range of industries, from aerospace to automotive to electronics. Its unique properties, such as high thermal conductivity and low friction, make it an ideal choice for many applications. However, in order to ensure the quality and performance of graphite products, it is essential to conduct hardness tests.

hardness testing is a crucial step in the manufacturing process of graphite products. By measuring the hardness of a material, manufacturers can determine its resistance to deformation and wear. This information is vital for ensuring that the graphite product will perform as expected in its intended application.

One of the key benefits of conducting hardness tests on graphite products is quality control. By testing the hardness of the material, manufacturers can identify any defects or inconsistencies in the production process. This allows them to make necessary adjustments to improve the overall quality of the product.

In addition to quality control, hardness testing also helps manufacturers to ensure the durability and longevity of graphite products. By measuring the hardness of the material, manufacturers can determine its ability to withstand wear and tear over time. This information is crucial for ensuring that the graphite product will have a long service life and perform reliably in its intended application.

Furthermore, hardness testing can also provide valuable insights into the performance of graphite products in specific environments. By measuring the hardness of the material under different conditions, manufacturers can assess how it will behave in real-world applications. This information is essential for ensuring that the graphite product will meet the performance requirements of its intended use.

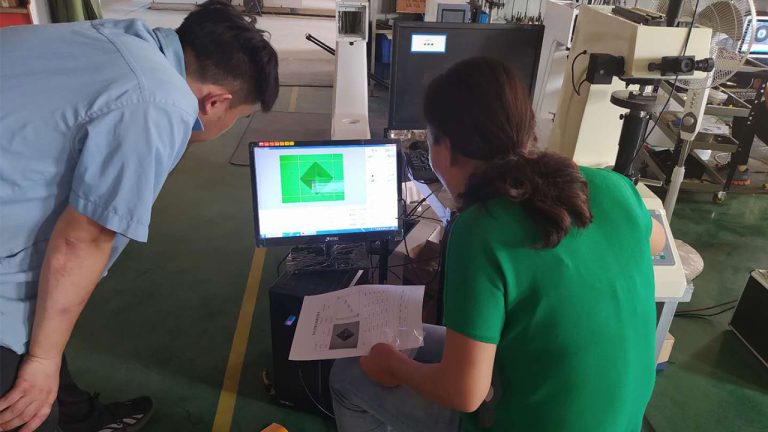

When it comes to conducting hardness tests on graphite products, Chinese high-quality factories are known for their expertise and precision. These factories use advanced testing equipment and techniques to accurately measure the hardness of graphite materials. This ensures that the products they produce meet the highest standards of quality and performance.

In addition to using state-of-the-art testing equipment, Chinese high-quality factories also employ skilled technicians who are trained in conducting hardness tests on graphite products. These technicians have the knowledge and experience to accurately interpret test results and make informed decisions about the quality of the material.

Overall, conducting hardness tests on graphite products is essential for ensuring their quality, durability, and performance. By working with Chinese high-quality factories that specialize in graphite manufacturing, manufacturers can be confident that their products will meet the highest standards of excellence. Hardness testing is a critical step in the production process that can help to ensure the success of graphite products in a wide range of applications.

Comparison of Hardness Testing Methods Used in Chinese High-Quality Graphite Factories

Graphite is a versatile material that is widely used in various industries, including aerospace, automotive, and electronics. Its unique properties, such as high thermal conductivity and low friction, make it an ideal choice for many applications. However, the quality of graphite can vary depending on the manufacturing process and the raw materials used. To ensure that the graphite meets the required specifications, hardness testing is essential.

There are several methods used to test the hardness of graphite in Chinese high-quality factories. One common method is the rockwell hardness test, which measures the resistance of a material to indentation. In this test, a diamond cone or steel ball is pressed into the surface of the graphite, and the depth of the indentation is measured. The Rockwell hardness value is then calculated based on the depth of the indentation.

Another popular method is the vickers hardness test, which uses a square-based diamond pyramid to create an indentation in the graphite. The size of the indentation is measured, and the Vickers hardness value is calculated based on the load applied and the surface area of the indentation. This method is often used for testing small samples or thin coatings of graphite.

A third method commonly used in Chinese high-quality graphite factories is the Knoop hardness test. This test is similar to the Vickers test but uses a rhombic-based diamond pyramid instead of a square-based one. The Knoop hardness value is calculated based on the load applied and the surface area of the indentation. This method is often preferred for testing brittle materials like graphite.

Each of these hardness testing methods has its advantages and limitations. The Rockwell test is quick and easy to perform, making it suitable for routine quality control checks. However, it may not be as accurate as the Vickers or Knoop tests for measuring the hardness of graphite. The Vickers test is more precise and can be used to test a wide range of materials, but it requires more sophisticated equipment and is more time-consuming. The Knoop test is ideal for testing brittle materials like graphite, but it may not be as widely used as the other methods.

In Chinese high-quality graphite factories, a combination of these hardness testing methods is often used to ensure the accuracy and reliability of the results. By using multiple testing methods, manufacturers can verify the hardness of the graphite from different perspectives and minimize the risk of errors or inconsistencies.

In conclusion, hardness testing is an essential part of quality control in Chinese high-quality graphite factories. By using a combination of Rockwell, Vickers, and Knoop hardness tests, manufacturers can ensure that the graphite meets the required specifications and performs optimally in various applications. These testing methods provide valuable insights into the hardness of graphite and help manufacturers maintain high standards of quality and performance.