Table of Contents

Benefits of Factory Customization for hardness testers

When it comes to hardness testers, factory customization offers a range of benefits that can greatly enhance the performance and efficiency of these essential tools. Factory customization allows for the tailoring of hardness testers to meet specific requirements and preferences, ensuring that they are perfectly suited to the needs of the user. This level of customization can result in improved accuracy, reliability, and overall functionality, making factory customization an attractive option for those looking to get the most out of their hardness testers.

One of the key benefits of factory customization for hardness testers is the ability to select the most appropriate testing methods and scales for a particular application. Different materials and components require different testing methods to accurately assess their hardness, and factory customization allows users to choose the methods that best suit their needs. This ensures that hardness testers are able to provide accurate and reliable results, leading to better quality control and product performance.

In addition to selecting the most appropriate testing methods, factory customization also allows for the calibration of hardness testers to ensure accurate and consistent results. Calibration is essential for maintaining the accuracy of hardness testers over time, as factors such as wear and tear can affect their performance. By calibrating hardness testers at the factory, users can be confident that they are receiving accurate and reliable results every time they use the equipment.

Another benefit of factory customization for hardness testers is the ability to incorporate additional features and capabilities that are not available in standard models. This can include features such as data logging, automatic calculations, and advanced reporting functions, all of which can streamline the testing process and improve efficiency. By customizing hardness testers with these additional features, users can save time and effort while still obtaining accurate and reliable results.

Factory customization also allows for the integration of hardness testers with other equipment and systems, such as automation systems and quality control software. This can further enhance the efficiency and effectiveness of hardness testing processes, allowing for seamless integration with existing workflows and systems. By customizing hardness testers to work in conjunction with other equipment and software, users can maximize the benefits of their investment and improve overall productivity.

Overall, factory customization offers a range of benefits for hardness testers that can greatly enhance their performance and efficiency. By tailoring hardness testers to meet specific requirements and preferences, users can ensure that they are getting the most out of their equipment. From selecting the most appropriate testing methods and scales to calibrating the equipment for accuracy, factory customization can help users achieve accurate and reliable results every time they use their hardness testers. Additionally, the ability to incorporate additional features and integrate with other equipment and systems can further improve efficiency and productivity. For those looking to maximize the benefits of their hardness testers, factory customization is a valuable option to consider.

How to Choose the Right hardness tester for Your Factory

When it comes to ensuring the quality and durability of your products, having the right hardness tester is essential. With so many options available on the market, choosing the best one for your factory can be a daunting task. However, with proper research and understanding of your specific needs, you can make an informed decision that will benefit your production process in the long run.

One of the key factors to consider when selecting a hardness tester for your factory is customization options. Factory customization allows you to tailor the hardness tester to meet your specific requirements and preferences. This can include features such as different testing methods, load ranges, and data analysis capabilities. By customizing your hardness tester, you can ensure that it is perfectly suited to your production needs, resulting in more accurate and reliable testing results.

When looking for a hardness tester with factory customization options, it is important to consider the reputation and experience of the manufacturer. Choose a company that has a proven track record of delivering high-quality, reliable hardness testers that meet the needs of their customers. Look for manufacturers that have a strong focus on innovation and continuous improvement, as this will ensure that you are getting the latest technology and features in your hardness tester.

Another important factor to consider when choosing a hardness tester with factory customization options is the level of technical support and training provided by the manufacturer. A good manufacturer will offer comprehensive training programs for your staff to ensure that they are able to operate the hardness tester effectively and efficiently. They should also provide ongoing technical support to help troubleshoot any issues that may arise during testing.

In addition to customization options, it is also important to consider the overall quality and durability of the hardness tester. Look for a tester that is made from high-quality materials and is built to withstand the rigors of daily use in a factory setting. A durable hardness tester will provide you with years of reliable service, saving you time and money in the long run.

When choosing a hardness tester with factory customization options, it is also important to consider your budget. While it may be tempting to opt for the cheapest option available, it is important to remember that quality and reliability should be your top priorities. Investing in a high-quality hardness tester with factory customization options may cost more upfront, but it will pay off in the long run with accurate and reliable testing results.

In conclusion, choosing the right hardness tester for your factory is a crucial decision that can have a significant impact on the quality and durability of your products. By opting for a hardness tester with factory customization options, you can tailor the tester to meet your specific needs and preferences, resulting in more accurate and reliable testing results. Consider factors such as the reputation of the manufacturer, technical support and training, quality and durability, and budget when making your decision. With the right hardness tester in place, you can ensure that your products meet the highest standards of quality and performance.

Case Studies: Successful Implementation of Factory Customized Hardness Testers

In the manufacturing industry, the quality control of products is of utmost importance. One crucial aspect of quality control is ensuring that the materials used in production meet the required hardness standards. Hardness testers are essential tools used to measure the hardness of materials, providing valuable data for manufacturers to make informed decisions about their products.

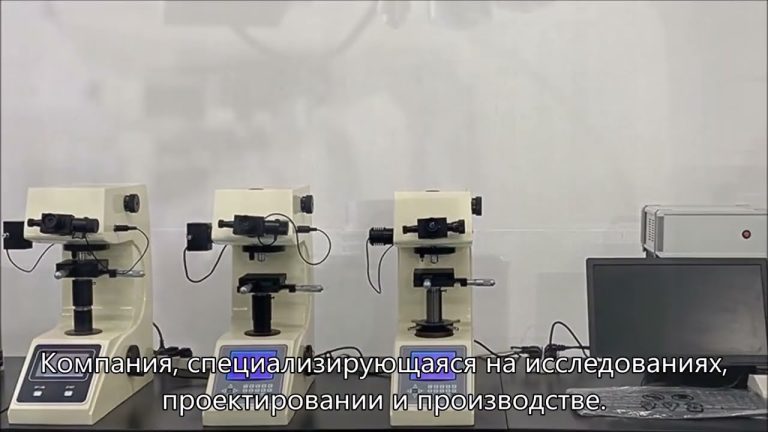

When it comes to hardness testers, one size does not fit all. Different industries have varying requirements when it comes to hardness testing, and off-the-shelf testers may not always meet these specific needs. This is where factory customization comes into play. Factory customization allows manufacturers to tailor hardness testers to their exact specifications, ensuring that they get the most accurate and reliable results.

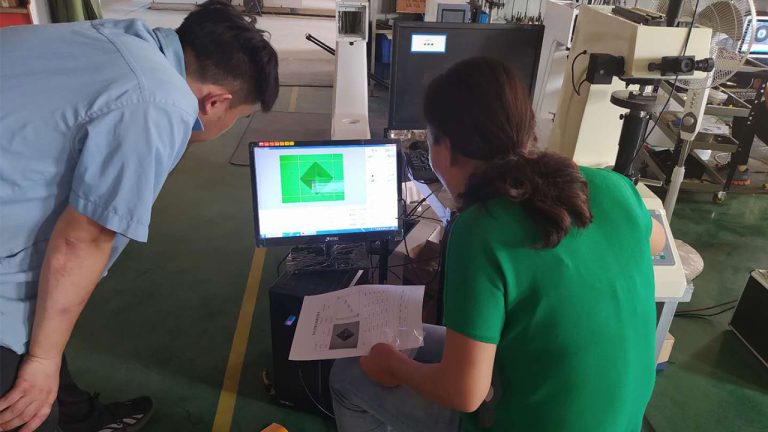

One company that has successfully implemented factory customization for their hardness testers is Factory Customization Best. They specialize in providing customized hardness testers for a wide range of industries, from automotive to aerospace. By working closely with their clients to understand their unique requirements, Factory Customization Best is able to design and manufacture hardness testers that meet and exceed expectations.

One of Factory Customization Best’s clients, a leading automotive manufacturer, was facing challenges with their current hardness testing equipment. The off-the-shelf tester they were using was not providing consistent and accurate results, leading to costly rejections and rework. After consulting with Factory Customization Best, they decided to invest in a customized hardness tester tailored to their specific needs.

The customized hardness tester designed by Factory Customization Best included features such as automated testing procedures, real-time data analysis, and customizable test parameters. This allowed the automotive manufacturer to streamline their testing process, improve accuracy, and reduce the risk of defects in their products. As a result, they were able to increase productivity and reduce costs, ultimately improving their bottom line.

Another success story comes from a leading aerospace manufacturer that was struggling with outdated hardness testing equipment. The off-the-shelf tester they were using was not capable of testing the wide range of materials used in their products, leading to inconsistencies in their testing results. After partnering with Factory Customization Best, they were able to design a customized hardness tester that could handle the diverse materials they worked with.

The customized hardness tester designed for the aerospace manufacturer included advanced testing algorithms, multiple testing modes, and compatibility with a wide range of materials. This allowed them to accurately test all the materials used in their products, ensuring that they met the required hardness standards. As a result, they were able to improve the quality of their products, reduce rejections, and increase customer satisfaction.

In conclusion, factory customization of hardness testers is a valuable tool for manufacturers looking to improve their quality control processes. By working with a company like Factory Customization Best, manufacturers can design and manufacture hardness testers that meet their specific requirements, leading to more accurate and reliable testing results. The case studies mentioned above demonstrate the benefits of factory customization and how it can help manufacturers achieve their quality control goals. If you are looking to improve your hardness testing processes, consider investing in a customized hardness tester tailored to your unique needs.