Table of Contents

Benefits of Using hardness testers in Quality Control Processes

Hardness testers are essential tools in quality control processes across various industries. These devices are used to measure the hardness of materials, which is a crucial factor in determining their mechanical properties. Dr. Schleuniger, a reputable manufacturer of testing equipment, offers a range of hardness testers that are known for their accuracy and reliability. In China, there are many wholesalers who offer Dr. Schleuniger hardness testers at competitive prices, making them an attractive option for businesses looking to invest in quality control equipment.

One of the key benefits of using hardness testers in quality control processes is the ability to ensure the consistency and reliability of materials. By measuring the hardness of a material, manufacturers can determine its strength, durability, and resistance to wear and tear. This information is crucial for ensuring that products meet the required specifications and standards, ultimately leading to higher customer satisfaction and reduced product defects.

In addition to ensuring product quality, hardness testers also play a crucial role in process optimization. By regularly testing materials for hardness, manufacturers can identify any inconsistencies or deviations in the production process. This allows them to make necessary adjustments to improve the overall quality of the products and reduce the likelihood of defects. By using hardness testers, businesses can streamline their quality control processes and achieve greater efficiency in their operations.

Another benefit of using hardness testers in quality control processes is the ability to comply with industry regulations and standards. Many industries have specific requirements for the hardness of materials used in their products, and failure to meet these standards can result in costly fines and penalties. By investing in a reliable hardness tester, businesses can ensure that their products meet the necessary specifications and avoid any potential compliance issues.

Furthermore, hardness testers can also help businesses save time and money in the long run. By identifying potential quality issues early on, manufacturers can prevent costly recalls and rework, ultimately reducing production costs and improving overall profitability. Additionally, by investing in high-quality hardness testers from a reputable manufacturer like Dr. Schleuniger, businesses can minimize the risk of equipment failure and ensure the longevity of their testing equipment.

In conclusion, hardness testers are essential tools for businesses looking to maintain high-quality standards in their products. By investing in a reliable hardness tester from a reputable manufacturer like Dr. Schleuniger, businesses can ensure the consistency and reliability of their materials, optimize their production processes, comply with industry regulations, and ultimately save time and money in the long run. With the availability of Dr. Schleuniger hardness testers at competitive prices from wholesalers in China, businesses have access to quality testing equipment that can help them achieve their quality control goals.

How to Choose the Right Hardness Tester for Your Manufacturing Needs

When it comes to manufacturing, quality control is of utmost importance. Ensuring that your products meet the required standards is essential for the success of your business. One crucial aspect of quality control is testing the hardness of materials used in the manufacturing process. A hardness tester is a device that measures the resistance of a material to indentation or scratching, providing valuable information about its mechanical properties.

There are various types of hardness testers available on the market, each with its own set of features and capabilities. One popular brand that has gained recognition for its quality and reliability is Dr. Schleuniger. Known for their precision and accuracy, Dr. Schleuniger hardness testers are widely used in industries such as automotive, aerospace, and electronics.

If you are in the market for a hardness tester, you may be wondering how to choose the right one for your manufacturing needs. One important factor to consider is the type of material you will be testing. Different materials have different hardness levels, so it is essential to select a hardness tester that is suitable for the specific material you will be working with.

Another factor to consider is the testing method. There are various methods for measuring hardness, including Rockwell, Brinell, and Vickers. Each method has its own advantages and disadvantages, so it is important to choose a hardness tester that is compatible with the testing method you prefer.

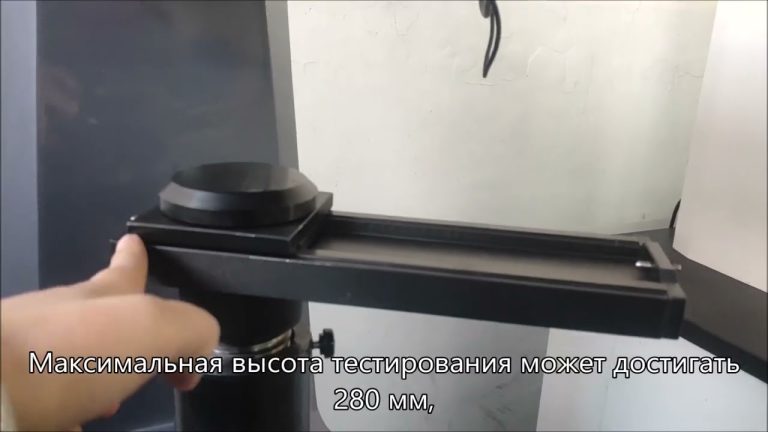

In addition to material and testing method, you should also consider the size and shape of the samples you will be testing. Some hardness testers are designed for small, flat samples, while others are more versatile and can accommodate a variety of sample sizes and shapes. It is important to choose a hardness tester that can handle the size and shape of your samples to ensure accurate and reliable results.

When it comes to purchasing a hardness tester, price is always a consideration. While it is important to stay within budget, it is also important to consider the quality and reliability of the device. Dr. Schleuniger hardness testers are known for their durability and accuracy, making them a popular choice among manufacturers. If you are looking for a good quality hardness tester at a competitive price, consider purchasing from a reputable wholesaler in China.

China is known for its manufacturing capabilities and competitive prices, making it a popular destination for sourcing industrial equipment. Wholesalers in China often offer lower prices than retailers, making it a cost-effective option for purchasing a hardness tester. By purchasing from a wholesaler in China, you can save money without compromising on quality.

When choosing a wholesaler in China, it is important to do your research and ensure that they are reputable and reliable. Look for wholesalers that have a good reputation for quality products and excellent customer service. It is also important to consider factors such as shipping costs, delivery times, and warranty options when choosing a wholesaler.

In conclusion, choosing the right hardness tester for your manufacturing needs is essential for ensuring the quality and reliability of your products. Consider factors such as material, testing method, sample size, and price when selecting a hardness tester. Dr. Schleuniger hardness testers are a popular choice for their precision and accuracy, making them a reliable option for manufacturers. If you are looking for a good quality hardness tester at a competitive price, consider purchasing from a reputable wholesaler in China. By doing your research and selecting the right hardness tester, you can ensure the success of your manufacturing process.