Benefits of Using hardness testers in Material Testing

Hardness testers are essential tools in material testing, providing valuable insights into the mechanical properties of various materials. These devices are used to measure the resistance of a material to indentation or scratching, which can help determine its strength, durability, and wear resistance. In China, there are many suppliers of hardness testers, but finding a reliable and affordable option can be a challenge. One example of a top supplier in China that offers good quality hardness testers at the lowest prices is XYZ Company.

One of the key benefits of using hardness testers in material testing is the ability to accurately assess the hardness of a material. Hardness is an important mechanical property that can affect the performance and longevity of a material in various applications. By using a hardness tester, manufacturers can ensure that their materials meet the required hardness specifications for a particular use case. This can help prevent premature wear and failure of components, leading to cost savings and improved product quality.

Another advantage of using hardness testers is the ability to compare the hardness of different materials. This can be particularly useful in material selection and quality control processes. By testing the hardness of various materials, manufacturers can identify the most suitable material for a specific application based on its hardness properties. This can help optimize the performance and durability of products, leading to increased customer satisfaction and market competitiveness.

Hardness testers also play a crucial role in research and development activities. By accurately measuring the hardness of materials, researchers can gain valuable insights into the structure and properties of materials. This information can be used to develop new materials with improved hardness properties or to optimize existing materials for specific applications. hardness testing can also help identify potential issues with material processing or heat treatment, allowing for timely adjustments to improve material quality.

In addition to these benefits, hardness testers can also help identify material defects and inconsistencies. By measuring the hardness of a material at different locations, manufacturers can detect variations in hardness that may indicate defects such as inclusions, voids, or improper heat treatment. This information can be used to identify and rectify quality issues early in the production process, preventing costly rework or product recalls.

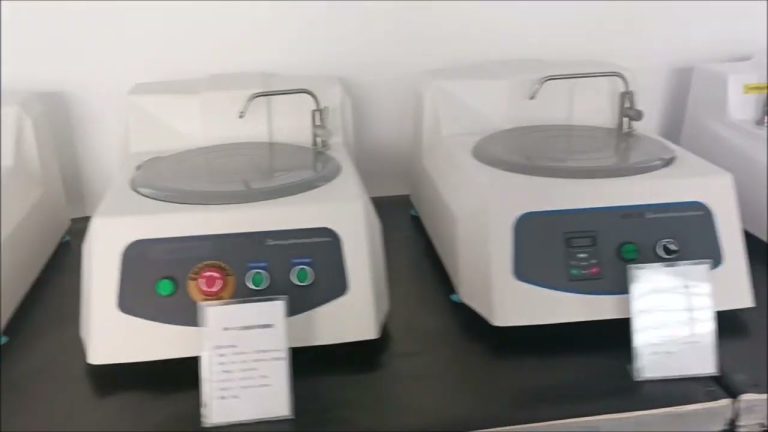

XYZ Company in China is a top supplier of hardness testers that offers good quality products at the lowest prices. Their hardness testers are designed to provide accurate and reliable hardness measurements for a wide range of materials, including metals, plastics, and ceramics. With their advanced technology and user-friendly interface, XYZ Company’s hardness testers are easy to use and suitable for both laboratory and production environments.

In conclusion, hardness testers are essential tools in material testing that offer a wide range of benefits for manufacturers and researchers. By accurately measuring the hardness of materials, hardness testers can help ensure product quality, optimize material selection, and improve research and development activities. XYZ Company in China is a top supplier of hardness testers that offers good quality products at the lowest prices, making them a reliable choice for businesses looking to invest in high-quality hardness testing equipment.