Benefits of Using a hardness tester in HV Factory Operations

In the manufacturing industry, particularly in high voltage (HV) factories, the quality control of products is of utmost importance. Ensuring that the materials used in the production process meet the required standards is crucial to the overall success of the operation. One tool that has become indispensable in this regard is the hardness tester.

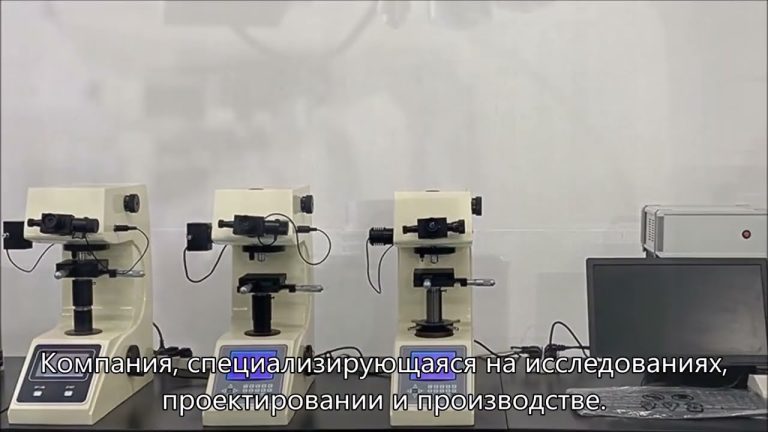

A hardness tester is a device used to measure the hardness of a material, which is a key indicator of its strength and durability. In HV factories, where materials are subjected to high levels of stress and pressure, having a reliable hardness tester can make a significant difference in the quality of the products being produced.

One of the main benefits of using a hardness tester in HV factory operations is the ability to quickly and accurately assess the hardness of materials. This allows manufacturers to identify any potential issues with the materials early on in the production process, preventing costly mistakes and ensuring that only high-quality products are being produced.

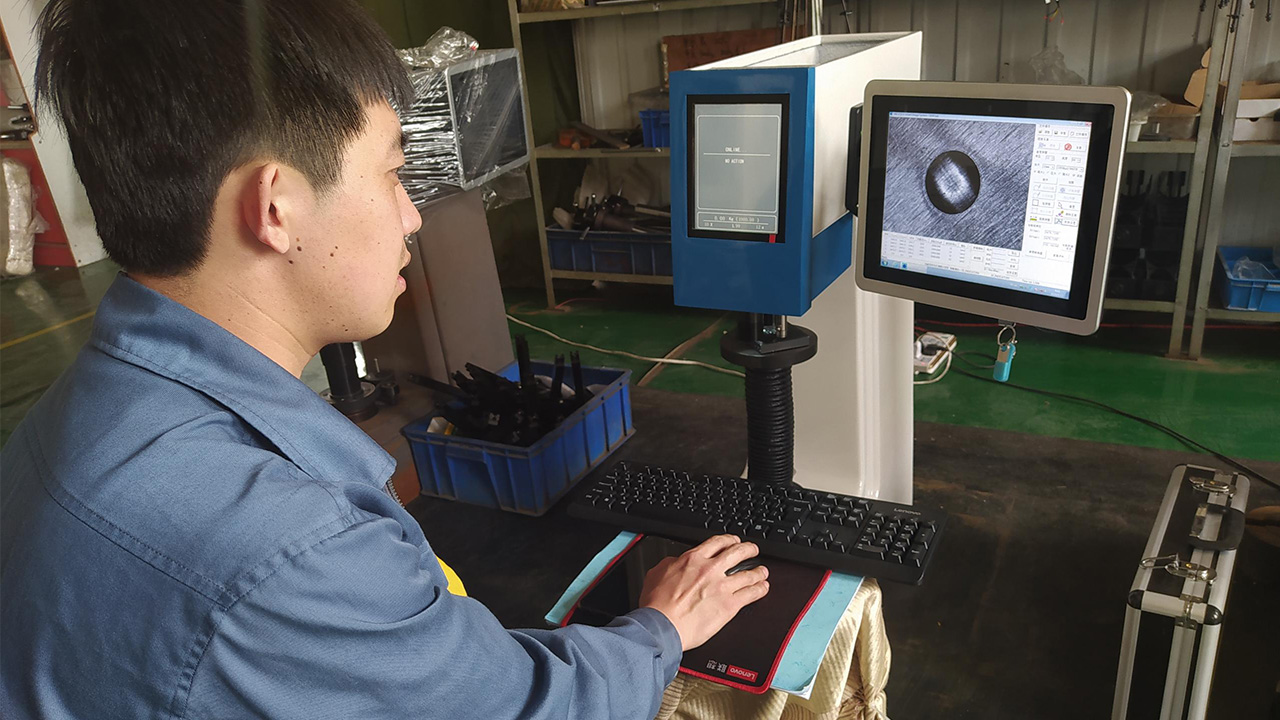

Furthermore, a hardness tester can help HV factories improve their overall efficiency. By providing real-time data on the hardness of materials, manufacturers can make informed decisions about the production process, such as adjusting the temperature or pressure settings to achieve the desired hardness levels. This can lead to a more streamlined and efficient production process, ultimately saving time and money.

Another benefit of using a hardness tester in HV factory operations is the ability to ensure consistency in the quality of products. By regularly testing the hardness of materials throughout the production process, manufacturers can identify any variations or inconsistencies and take corrective action to ensure that all products meet the required standards. This can help build trust with customers and enhance the reputation of the factory.

Additionally, a hardness tester can help HV factories comply with industry regulations and standards. Many industries have specific requirements for the hardness of materials used in their products, and a hardness tester can provide the necessary data to demonstrate compliance. This can help HV factories avoid costly fines and penalties for non-compliance.

Overall, the benefits of using a hardness tester in HV factory operations are clear. From improving efficiency and consistency to ensuring compliance with industry standards, a hardness tester is a valuable tool that can help manufacturers produce high-quality products and maintain a competitive edge in the market.

In conclusion, the use of a hardness tester in HV factory operations is essential for ensuring the quality and reliability of products. By providing accurate and timely data on the hardness of materials, a hardness tester can help manufacturers make informed decisions, improve efficiency, and ensure compliance with industry standards. Investing in a hardness tester is a wise decision for any HV factory looking to enhance its production process and deliver high-quality products to customers.