Benefits of Using a hardness tester for Metal Testing

When it comes to testing the hardness of metals, a hardness tester is an essential tool for ensuring the quality and durability of metal components. In the manufacturing industry, the hardness of metal parts can have a significant impact on their performance and longevity. By using a hardness tester, manufacturers can accurately measure the hardness of metal samples and make informed decisions about their suitability for specific applications.

One of the key benefits of using a hardness tester for metal testing is the ability to obtain precise and reliable measurements. hardness testers are designed to provide accurate readings of the hardness of metal samples, allowing manufacturers to assess the quality of their products with confidence. This level of precision is essential for ensuring that metal components meet the required standards for strength and durability.

In addition to providing accurate measurements, hardness testers are also easy to use and require minimal training to operate. This makes them an ideal tool for manufacturers who need to quickly and efficiently test the hardness of metal samples. With a hardness tester, manufacturers can streamline their testing processes and ensure that their products meet the necessary quality standards.

Another benefit of using a hardness tester for metal testing is the ability to identify potential defects or inconsistencies in metal samples. By measuring the hardness of metal components, manufacturers can detect any variations in hardness that may indicate flaws in the material or manufacturing process. This information can help manufacturers identify and address issues before they impact the performance or reliability of their products.

Furthermore, hardness testers are versatile tools that can be used to test a wide range of metal samples, including steel, aluminum, and copper. This versatility makes hardness testers a valuable investment for manufacturers who work with a variety of metal materials. By using a hardness tester, manufacturers can ensure that all of their metal components meet the necessary hardness requirements for their intended applications.

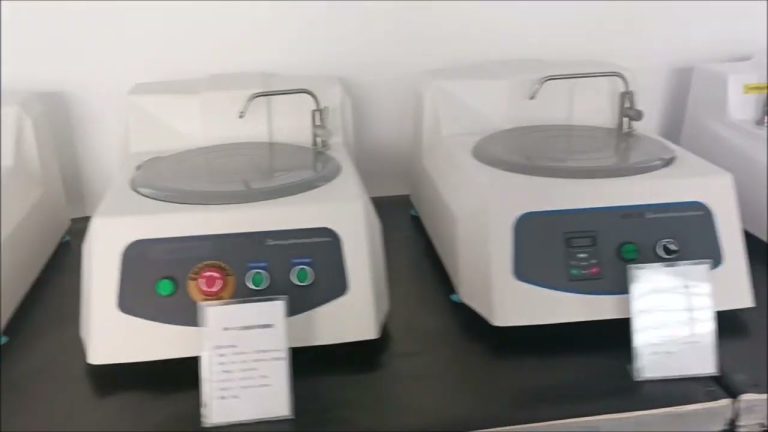

In addition to their accuracy and versatility, hardness testers are also cost-effective tools for metal testing. Chinese high-quality affordable suppliers offer a range of hardness testers at competitive prices, making them accessible to manufacturers of all sizes. By investing in a hardness tester, manufacturers can save time and money on testing processes and ensure the quality of their products without breaking the bank.

Overall, the benefits of using a hardness tester for metal testing are clear. From providing accurate measurements to identifying defects and inconsistencies, hardness testers are essential tools for ensuring the quality and durability of metal components. With Chinese high-quality affordable suppliers offering a range of hardness testers, manufacturers can easily access the tools they need to test the hardness of their metal samples and produce high-quality products that meet the necessary standards.