Table of Contents

Benefits of Using hardness testing Equipment in Quality Control Processes

Hardness testing equipment plays a crucial role in quality control processes across various industries. From manufacturing to construction, the ability to accurately measure the hardness of materials is essential for ensuring product quality and performance. In China, there is a growing demand for high-quality hardness testing equipment, and wholesalers are stepping up to meet this need.

One of the key benefits of using hardness testing equipment in quality control processes is the ability to ensure consistency and reliability in material properties. By accurately measuring the hardness of a material, manufacturers can identify any variations or defects that may affect the performance of the final product. This level of precision is essential for meeting industry standards and customer expectations.

In addition to ensuring product quality, hardness testing equipment can also help manufacturers optimize their production processes. By identifying the hardness of materials at various stages of production, manufacturers can make informed decisions about processing parameters and material selection. This can lead to improved efficiency, reduced waste, and ultimately, cost savings.

Another benefit of using hardness testing equipment in quality control processes is the ability to detect material degradation or wear over time. By regularly testing the hardness of materials, manufacturers can identify any changes that may indicate the need for maintenance or replacement. This proactive approach can help prevent costly downtime and ensure the longevity of equipment and products.

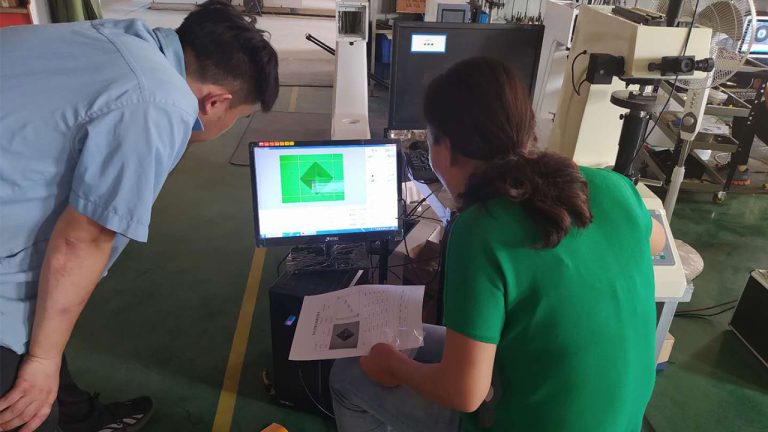

Wholesalers in China are recognizing the importance of providing high-quality hardness testing equipment to meet the growing demand in the market. By offering a wide range of products at competitive prices, wholesalers are helping manufacturers access the tools they need to maintain quality control processes and meet industry standards.

When choosing a wholesaler for hardness testing equipment, it is important to consider factors such as product quality, reliability, and customer support. Wholesalers that offer high-quality products from reputable manufacturers can provide peace of mind to customers who rely on these tools for their quality control processes. Additionally, wholesalers that offer competitive pricing and flexible payment options can help manufacturers manage their budgets effectively.

In conclusion, hardness testing equipment plays a critical role in quality control processes across various industries. By accurately measuring the hardness of materials, manufacturers can ensure product quality, optimize production processes, and detect material degradation over time. Wholesalers in China are meeting the growing demand for high-quality hardness testing equipment by offering a wide range of products at competitive prices. By choosing a reputable wholesaler, manufacturers can access the tools they need to maintain quality control processes and meet industry standards.

How to Choose the Right Hardness Testing Equipment Supplier in China

When it comes to choosing the right hardness testing equipment supplier in China, there are several factors that you need to consider to ensure that you are getting high-quality products at a wholesale price. With the market flooded with various suppliers, it can be overwhelming to make the right choice. However, by following these tips, you can make an informed decision and find a reliable wholesaler that meets your needs.

First and foremost, it is essential to do thorough research on the different suppliers available in China. Look for suppliers that have a good reputation in the industry and have a track record of providing high-quality hardness testing equipment. You can check online reviews and testimonials from other customers to get an idea of the supplier’s reliability and quality of products.

Additionally, it is crucial to consider the range of products that the supplier offers. A good supplier should have a wide selection of hardness testing equipment to choose from, including different types of testers and accessories. This will allow you to find the right equipment that suits your specific needs and requirements.

Furthermore, it is important to consider the pricing of the hardness testing equipment. While you may be looking for wholesale prices, it is essential to ensure that the quality of the products is not compromised. Look for suppliers that offer competitive prices without compromising on the quality of the equipment. You can also negotiate with the supplier to get the best possible price for the products you need.

Another important factor to consider when choosing a hardness testing equipment supplier in China is the after-sales service and support. A good supplier should provide excellent customer service and technical support to help you with any issues or questions you may have regarding the equipment. This will ensure that you have a smooth and hassle-free experience when using the products.

In addition to these factors, it is also important to consider the shipping and delivery options offered by the supplier. Look for suppliers that offer fast and reliable shipping services to ensure that you receive your products in a timely manner. You should also consider the shipping costs and any additional fees that may be associated with the delivery of the products.

Overall, choosing the right hardness testing equipment supplier in China requires careful consideration of various factors, including the supplier’s reputation, product range, pricing, after-sales service, and shipping options. By doing thorough research and taking these factors into account, you can find a reliable wholesaler that offers high-quality products at a competitive price. This will ensure that you get the best value for your money and have a positive experience when purchasing hardness testing equipment from China.