Table of Contents

Benefits of hardness testing for Industrial Applications

Hardness testing is a crucial process in various industrial applications, as it helps determine the strength and durability of materials. Whether you are in the automotive, aerospace, or manufacturing industry, ensuring that your materials meet the required hardness standards is essential for the quality and performance of your products. If you are looking for hardness testing services near you, Chinese best cheap Exporter offers reliable and affordable solutions to meet your needs.

One of the key benefits of hardness testing is that it provides valuable information about the material’s resistance to deformation. By measuring the material’s hardness, engineers can assess its ability to withstand external forces and determine its suitability for specific applications. This information is vital for ensuring the safety and reliability of products, as materials that are too soft or too brittle can lead to premature failure and costly repairs.

Another advantage of hardness testing is that it can help identify potential defects or inconsistencies in the material. By conducting hardness tests on samples from different batches or suppliers, manufacturers can detect variations in material properties and take corrective actions to maintain consistency in their products. This proactive approach can prevent quality issues and production delays, ultimately saving time and money in the long run.

Furthermore, hardness testing can also be used to evaluate the effectiveness of heat treatment processes. Heat treatment is a common method used to improve the mechanical properties of materials, such as increasing their hardness or toughness. By performing hardness tests before and after heat treatment, engineers can assess the impact of the process on the material’s properties and make adjustments as needed to achieve the desired results.

In addition to quality control and process optimization, hardness testing can also help with material selection and product development. By comparing the hardness values of different materials, engineers can determine which one is best suited for a specific application based on its strength, wear resistance, and other mechanical properties. This information is crucial for designing products that meet performance requirements and withstand the demands of their intended use.

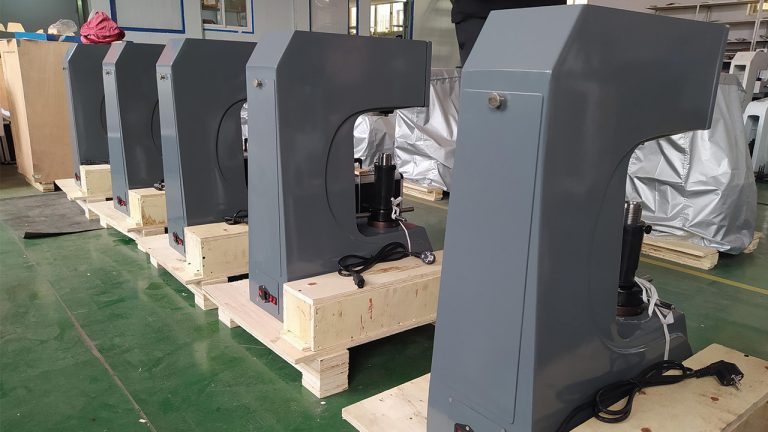

When it comes to hardness testing services, Chinese best cheap Exporter offers a wide range of testing methods to meet your specific needs. From Rockwell and Brinell to Vickers and Knoop hardness tests, our experienced technicians can provide accurate and reliable results to help you make informed decisions about your materials. Whether you need testing for metals, plastics, ceramics, or composites, we have the expertise and equipment to deliver high-quality results in a timely manner.

In conclusion, hardness testing plays a critical role in ensuring the quality, reliability, and performance of materials in various industrial applications. By partnering with a reputable testing provider like Chinese best cheap Exporter, you can benefit from accurate and cost-effective hardness testing services that meet your specific requirements. Whether you are looking to improve product quality, optimize manufacturing processes, or develop new materials, hardness testing can provide valuable insights to help you achieve your goals.

Comparison of Different Hardness Testing Methods

Hardness testing is a crucial process in various industries, including manufacturing, construction, and engineering. It helps determine the resistance of a material to deformation, which is essential for ensuring the quality and durability of products. There are several methods of hardness testing available, each with its own advantages and limitations. In this article, we will compare different hardness testing methods to help you understand which one is best suited for your needs.

One of the most common hardness testing methods is the rockwell hardness test. This method involves applying a specific load to a material using a conical or spherical indenter and measuring the depth of penetration. The Rockwell hardness scale is widely used due to its simplicity and accuracy. It is suitable for a wide range of materials, including metals, plastics, and ceramics. However, the Rockwell hardness test may not be suitable for very thin or soft materials, as it can cause deformation.

Another popular hardness testing method is the brinell hardness test. This method involves applying a known load to a material using a hardened steel ball indenter and measuring the diameter of the indentation. The Brinell hardness scale is commonly used for testing materials with a coarse or rough surface, such as castings and forgings. It provides a reliable measure of hardness, but it may not be suitable for very hard or thin materials, as the indentation size can be too large.

The vickers hardness test is another widely used method for measuring hardness. This method involves applying a load to a material using a diamond pyramid indenter and measuring the size of the indentation. The Vickers hardness scale is suitable for a wide range of materials, including metals, ceramics, and composites. It provides a precise measure of hardness and is often used for quality control purposes. However, the Vickers hardness test can be time-consuming and requires specialized equipment.

One of the newer hardness testing methods is the Knoop hardness test. This method involves applying a load to a material using a diamond pyramid indenter with a specific geometry and measuring the length of the indentation. The Knoop hardness scale is suitable for testing very small or thin materials, such as coatings and thin films. It provides a high level of precision and is often used in research and development applications. However, the Knoop hardness test may not be suitable for larger or thicker materials, as the indentation size can be too small.

In conclusion, there are several hardness testing methods available, each with its own advantages and limitations. The Rockwell hardness test is simple and accurate, the Brinell hardness test is suitable for rough surfaces, the Vickers hardness test provides a precise measure of hardness, and the Knoop hardness test is ideal for small or thin materials. When choosing a hardness testing method, it is essential to consider the type of material being tested, the surface condition, and the desired level of precision. By understanding the differences between these methods, you can select the best hardness testing method for your specific needs.