Benefits of Using Instron hardness tester for Quality Control in Manufacturing Processes

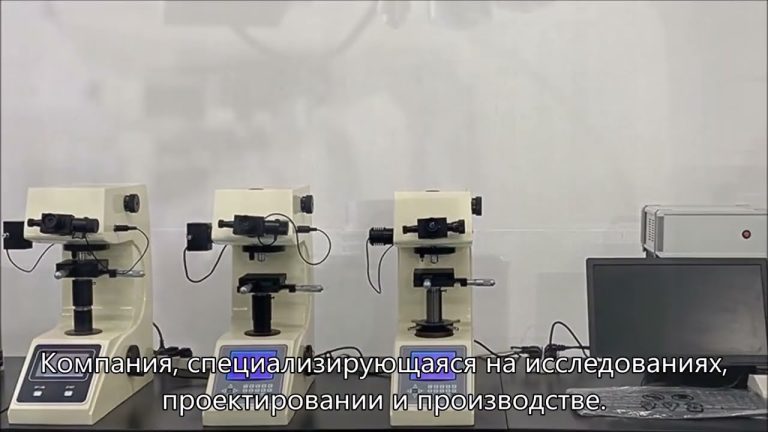

Quality control is a crucial aspect of any manufacturing process, ensuring that products meet the required standards and specifications. In the realm of material testing, the Instron hardness tester has emerged as a reliable tool for assessing the hardness of various materials. In China, Instron hardness testers are widely used in manufacturing industries due to their accuracy, efficiency, and reliability.

One of the key benefits of using an Instron hardness tester for quality control in manufacturing processes is its ability to provide precise and consistent hardness measurements. The Instron hardness tester utilizes advanced technology to accurately measure the resistance of a material to indentation, providing a quantitative measure of its hardness. This level of precision is essential for ensuring that products meet the required hardness specifications, preventing defects and ensuring product quality.

In addition to precision, the Instron hardness tester offers efficiency in the testing process. With automated features and user-friendly interfaces, Instron hardness testers streamline the testing process, allowing for quick and efficient hardness measurements. This efficiency is particularly beneficial in high-volume manufacturing environments, where rapid testing is essential for maintaining production schedules and meeting customer demands.

Furthermore, the reliability of Instron hardness testers makes them a valuable tool for quality control in manufacturing processes. Instron hardness testers are designed to withstand the rigors of industrial environments, providing consistent and reliable hardness measurements over time. This reliability ensures that manufacturers can trust the accuracy of their hardness testing results, leading to improved product quality and customer satisfaction.

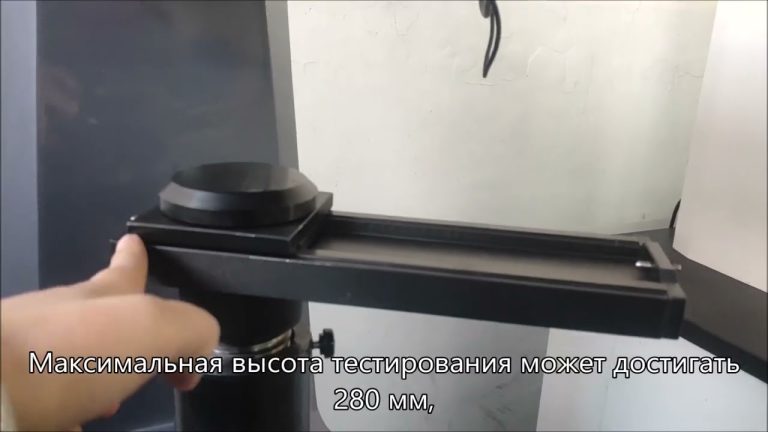

Another advantage of using an Instron hardness tester for quality control in manufacturing processes is the versatility it offers. Instron hardness testers are capable of testing a wide range of materials, from metals and alloys to plastics and composites. This versatility allows manufacturers to use a single testing instrument for a variety of materials, simplifying the testing process and reducing the need for multiple testing devices.

Additionally, Instron hardness testers are equipped with advanced features that enhance the testing capabilities and flexibility of the instrument. Features such as automatic data logging, customizable test parameters, and multiple testing modes allow manufacturers to tailor their hardness testing process to meet specific requirements and standards. This level of customization ensures that manufacturers can achieve accurate and reliable hardness measurements for their products.

In conclusion, the Instron hardness tester is a valuable tool for quality control in manufacturing processes, offering precision, efficiency, reliability, and versatility. In China, Instron hardness testers are widely used in manufacturing industries for their ability to provide accurate and consistent hardness measurements, streamline the testing process, withstand industrial environments, and test a wide range of materials. By utilizing an Instron hardness tester for quality control, manufacturers can ensure that their products meet the required hardness specifications, leading to improved product quality and customer satisfaction.