The metallographic mounting press, also known as the metallographic specimen mounting press, is suitable for pressing thermosetting plastics for small and non-regular metallographic specimens that are not in a regular shape and not easy to handle. In the sample preparation process of metallographic analysis, the orientation adjustment of the observation surface before grinding and polishing is usually achieved by using mounting resin to fix the sample orientation. Meanwhile, mounting can transform irregular samples into shapes that are easy to hold by hand, thereby facilitating the control of the grinding and polishing process.

Metallographic mounting typically refers to the process of encapsulating metal samples with thermosetting resin. After the action of a certain temperature and pressure, it cools and takes shape. This process of heating and shaping is called hot mounting, and the equipment used for this process is called a metallographic mounting press or a metallographic hot mounting sample press.

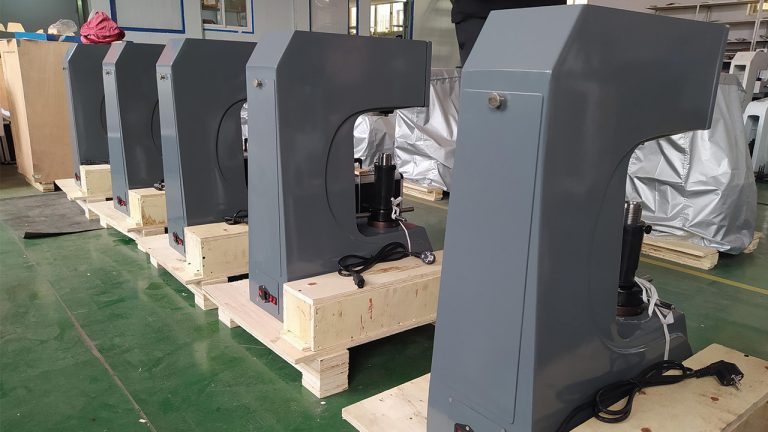

According to the different degrees of automation, metallographic hot mounting presses can be divided into manual simple type and automatic efficient type. The mounting process of the manual simple type is achieved through electrically controlled heating, manual pressurization, and natural air cooling. It has a simple structure, is easy to operate, but has a low efficiency. The mounting process of the automatic efficient type is fully automatic control, featuring functions such as intelligent temperature control heating, dynamic automatic pressure control by air pressure or hydraulic pressure, and intelligent water-saving cooling control, resulting in high sample preparation efficiency and good quality.

The manual mounting press belongs to the mechanical type. By rotating the handwheel outside the machine body, a pair of bevel gears drives the lead screw inside the machine body to move the lower mold for pressing the specimen up and down within the rigid mold sleeve. The thermosetting plastic along with the mounted specimen takes shape under heating conditions. The forming pressure during the specimen preparation process is automatically compensated by the spring fixed inside the machine body, and the pressure for pressing the specimen can be indicated by the signal light. However, the manual operation has more steps and is suitable for small and medium-sized laboratories with a small sample preparation volume.

With the wider application of the metallographic analysis method, especially the requirements for improving efficiency and ensuring sample preparation quality in the mounting and grinding and polishing of metallographic sample preparation in factory online quality control, the fully automatic hot mounting press emerged. It utilizes mature modern liquid supply control technology to optimize and automatically control the steps in the hot mounting process, thereby obtaining the maximum sample preparation efficiency while ensuring the mounting quality.