No products were found matching your selection.

Other Related Products

-

The HBRVS-187.5 Digital Brinell, Rockwell, and Vickers Hardness Tester features a novel appearance, comprehensive functionality, easy operation, clear and intuitive display, and stable performance. It integrates optics, machinery, and electronics as a high-tech product. Capable of conducting Brinell, Rockwell, and Vickers hardness tests with multiple test forces to meet various hardness testing requirements, it offers high testing accuracy, simple operation, high sensitivity, and stable readings. Equipped with a built-in printer, it can also be optionally connected to a computer via an RS232 data cable to export measurement reports.

-

The HBS-62.5AT Touch Screen Digital Automatic Turret Low Load Brinell Hardness Tester utilizes an 8-inch touch screen and a high-speed ARM processor, offering intuitive display, user-friendly human-machine interaction, and simple operation. With fast computation speeds, extensive database storage, automatic data correction, and data trend report capabilities.

-

This mill is a single disc machine, suitable for pre-grinding, grinding and polishing of metallographic samples. The machine through the inverter frequency regulation, can directly obtain the speed between 50~1400 RPM, so that the machine has more extensive application. It is an essential device for users to make metallographic samples. This machine has a cooling device to cool the specimen during pregrinding to prevent damage to the specimen from overheating. The machine is convenient to use and reliable, and is the ideal sampling equipment for factories, scientific research units and colleges and universities.

-

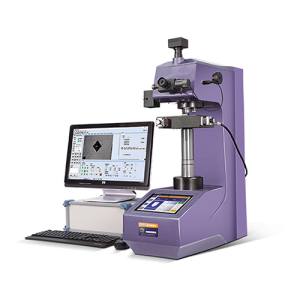

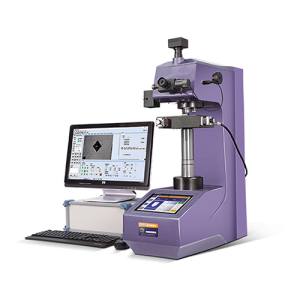

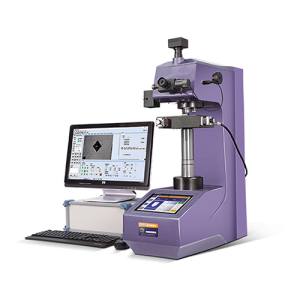

- Automatic loading, retention and unloading

- Autofocus, automatic measurement

- Workbench XYZ axis is fully automatic operation

- With a panoramic scanning function

- 17 kinds of path planning, free setting

-

ZXQ-2Q automatic metallographic prototype (pneumatic), suitable for small, not easy to hold or irregular metallographic and lithographic specimens, so as to cut the cutting or grinding and polishing, and then metallographic, spectral detection or hardness test. In the process of sample preparation, the machine through the program control, its automatic heating, pressure, automatic cooling to automatic pressure discharge stop a series of actions, to achieve the mechanism sample can be unattended effect, reflecting the machine more humanized, simple operation, superb efficiency of the superior characteristics.

-

The HR-150A manual Rockwell hardness tester is a universal type of Rockwell hardness tester. It utilizes mechanical manual testing, requires no power source, offers wide applicability, ease of operation, and demonstrates good cost-effectiveness and practicality.

-

HV(S)-5/10/30/50(A)T Touchscreen (Digital) (Automatic Turret) Vickers Hardness Tester utilizes an 8-inch touchscreen and high-speed ARM processor, offering an intuitive display, user-friendly interaction, and straightforward operation. It provides fast computation speed, massive database storage, automatic data correction, and offers data trend line reports.

-

The HB-3000ET touch screen electronic Brinell hardness tester can display hardness values on an LCD screen and allows for the display and setting of testing scales, test forces, indenter types, hold times, and unit conversions.

-

ZXQ-2Y automatic inlay machine is an advanced hydraulic water-cooled type automatic sample inlay equipment, unique cold and hot separation design, the sample inlay time to 6 minutes, greatly improve the work efficiency, inlay process controlled by automatic program, implements the heating, pressure, pressure, cooling, pressure discharge inlay process of one-key operation, no operator unattended, automatically complete sample inlay.