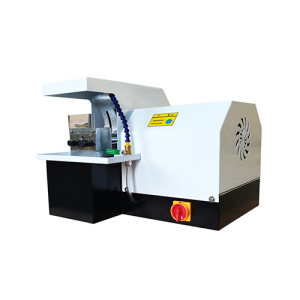

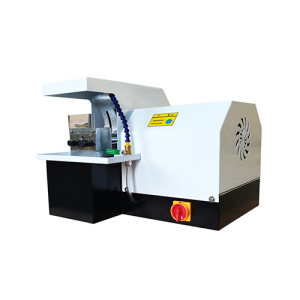

Q-2A Gold Phase Sample Cutting Machine

Q-2A metallographic sample cutting machine is a high-speed rotating sheet grinding wheel to intercept metallographic sample, which is widely used in metallographic laboratory cutting of various metal materials.

Q-2A metallographic sample cutting machine is a high-speed rotating sheet grinding wheel to intercept metallographic sample, which is widely used in metallographic laboratory cutting of various metal materials.

This mill is a desktop double-disc double-control grinding machine, suitable for rough grinding, fine grinding and polishing of gold test samples.

The new HRSS-150 Digital Rockwell Hardness Tester is a multi-functional hardness tester that integrates Rockwell, superficial Rockwell, and plastic Rockwell measurements. It features an 8-inch touch screen and a high-speed ARM processor, providing intuitive display, user-friendly interaction, and easy operation.

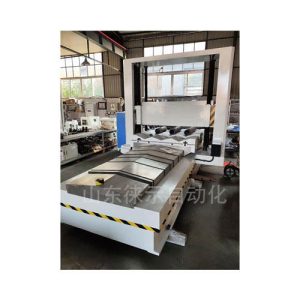

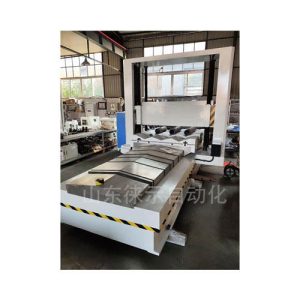

This machine is suitable for cutting the samples of various metal and non-metallic materials to observe the metallographic and lithofacies organization.

The HRD-150S Electric Digital Rockwell Hardness Tester features digital display of hardness values. It utilizes a motor to control the application, dwell, and unloading of test force, providing the option to select dwell time. The equipment offers simple and rapid operation with high sensitivity and stability, minimizing human error in operation and reading.

The HBS-3000AET Touch Screen Digital Brinell Hardness Tester features an 8-inch touch screen and a high-speed ARM processor, providing intuitive display, user-friendly human-machine interaction, and simple operation. It operates at high calculation speeds, offers extensive database storage, automatic data correction, and provides data trend line reports.

This cutting machine is suitable for accurate cutting of thin, small and light special materials with diameter less than 20mm, especially for cutting high value brittle intraocular lens.

This hardness tester adopts advanced design concepts. Advanced technologies in mechanical, electrical, and optical aspects are employed in the field of hardness testers today. The test results are precise, with strong repeatability. Equipped with Brinell hardness image processing system, it offers high automation, low labor intensity for operators, minimal human error, and a novel and appealing appearance. It is one of the most advanced Brinell hardness testers domestically and can fully replace similar imported products. It can quickly and accurately measure the Brinell hardness value of the test piece.