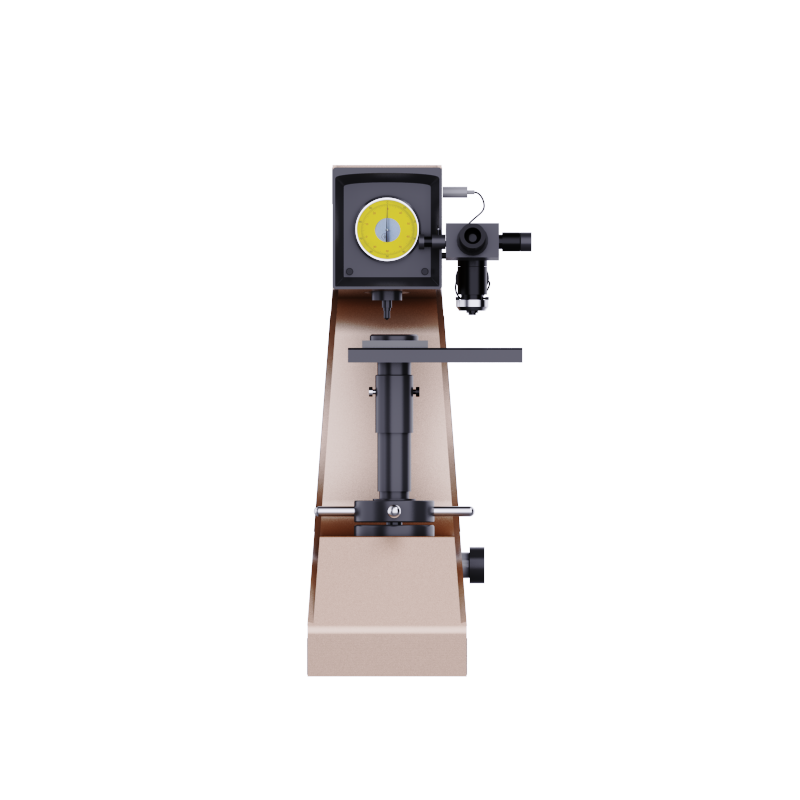

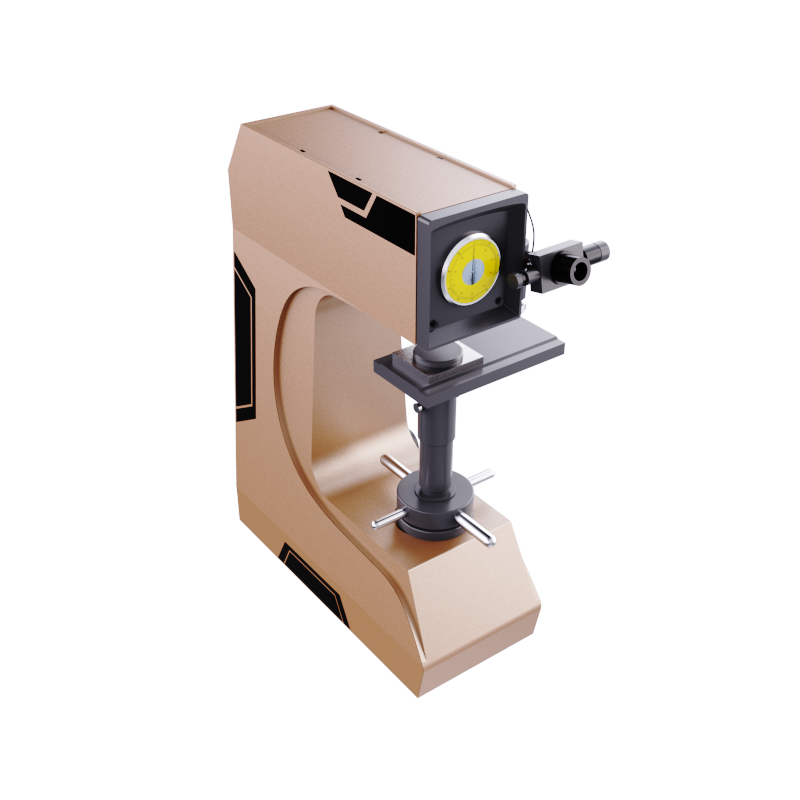

HBRVD-187.5 Motorized Brinell, Rockwell, And Vickers Hardness Tester

The HBRVD-187.5 Motorized Brinell, Rockwell, and Vickers Hardness Tester features a novel appearance, comprehensive functionality, convenient operation, clear and intuitive display, and stable performance. It is capable of conducting Brinell, Rockwell, and Vickers hardness tests with multiple test forces to meet various hardness testing requirements. This product offers high testing accuracy, simple operation, high sensitivity, and stable readings.

Product Concept

The HBRVD-187.5 Motorized Brinell, Rockwell, and vickers hardness tester features a novel appearance, comprehensive functionality, convenient operation, clear and intuitive display, and stable performance. It is capable of conducting Brinell, Rockwell, and Vickers hardness tests with multiple test forces to meet various hardness testing requirements. This product offers high testing accuracy, simple operation, high sensitivity, and stable readings.

Product Introduction

- The machine body is cast in one piece through casting technology and undergoes long-term aging treatment. Compared with assembled plate technology, it exhibits minimal deformation over extended usage periods and can adapt to various harsh environments.

- Automotive paint with high-quality finish and strong scratch resistance retains its brightness for many years of use.

- Capable of conducting Brinell, Rockwell, and Vickers hardness tests with seven levels of test forces to meet diverse hardness testing requirements.

- Direct reading of Rockwell hardness on the dial; Brinell and Vickers hardness measured through a high-definition optical system.

- Motor-controlled loading, unloading, and holding processes reduce human operational errors.

- Lever loading, frictionless main spindle, ensuring high precision in test force application.

Application Range

- Measurement of Brinell, Vickers, and Rockwell hardness for ferrous metals, non-ferrous metals, and hard alloys.

- Brinell hardness testing for castings, annealed steel, normalized steel, non-ferrous metals, and soft alloys.

- rockwell hardness testing for quenched and tempered materials.

- Vickers hardness testing for nitrided layers, ceramics, thin sheets, metal foils, plating layers, and tiny components.

Technical Specifications

|

Model |

HBRVD-187.5 | |

|

Total Test Force |

Luo’s | 60kgf,100kgf,150kgf(588N,980N,1471N) |

| The Cloth |

31.25kgf,62.5kgf,187.5kgf(306.5N,612.9N,1839N) |

|

| Victorinox |

30kgf,100kgf( 294.2N,980.7N) |

|

| Scale Type |

Luo’s |

HRA、HRB、HRC |

|

The Cloth |

HBW2.5/31.25 、HBW2.5/62.5

HBW5/62.5 、HBW2.5/187.5 |

|

| Victorinox |

HV30、HV100 |

|

|

Test Hardness Range |

Luo’s | 20-95HRA、10-100HRBW、20-70HRC |

| The Cloth |

5-650HBW |

|

| Victorinox |

5-3000HV |

|

|

Amplified Factor |

25X、50X、100X | |

|

Pressure Head Center To The Fuselage Distance |

160mm |

|

| Maximum Height Is Allowed For The Specimen | Luo’s |

200mm(the limit) |

| Busch, Vessel |

180mm |

|

|

Outline Dimension |

550*290*730mm | |

| Weight |

80kg |

|

Standard Configuration Of Accessories

|

Daping Workbench |

One piece | Xiaoping Workbench | One piece |

|

Type V Wkbench |

One piece | Diamond Rocch Head φ 1.588mm Hard Metal Carbide Ball Pressure Head | One of Each |

| φ 2.5, φ 5mm Hard Carbide Ball Pressure Head | One of Each | Diamond Vickers Head |

One piece |

| Standard Rockwell Hardness Blocks | Five pieces | Standard Brinell Hardness BlockStandard Vickers Hardness Block |

One of Each |

|

Eyepiece 2.5X, 5X And 10X |

One of Each |

|

The above is the standard configuration. Actual products are subject to physical objects.