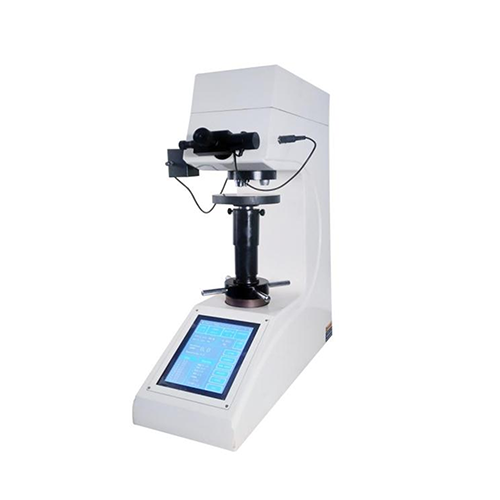

HBS-62.5AT Touch Screen Digital Automatic Turret Low Load Brinell Hardness Tester

The HBS-62.5AT Touch Screen Digital Automatic Turret Low Load Brinell Hardness Tester utilizes an 8-inch touch screen and a high-speed ARM processor, offering intuitive display, user-friendly human-machine interaction, and simple operation. With fast computation speeds, extensive database storage, automatic data correction, and data trend report capabilities.

Product Overview

The HBS-62.5AT Touch Screen Digital Automatic Turret Low Load brinell hardness tester utilizes an 8-inch touch screen and a high-speed ARM processor, offering intuitive display, user-friendly human-machine interaction, and simple operation. With fast computation speeds, extensive database storage, automatic data correction, and data trend report capabilities.

Product Features

- The body is crafted from high-quality cast iron, single-cast, and treated with automotive paint for an aesthetically pleasing appearance.

- Equipped with an automatic turret function, enabling automatic switching between the indenter and lens for added convenience.

- Convenient control system enabling automatic unit conversion across all hardness scales.

- Electronically closed-loop controls are used to apply the test force, achieving fully automated loading, holding, and unloading operations.

- Allows for setting the maximum and minimum hardness values; emitting an alarm sound when the test value exceeds the set range.

- Offers software hardness value correction, enabling direct correction of hardness values within a certain range.

- Provides a database function that automatically groups and saves test data, capable of storing over 2000 data points.

- Includes hardness value curve display functionality, visually demonstrating changes in hardness values.

- Equipped with a wireless Bluetooth printer and supports data output through RS232 and optional USB interfaces.

- Optional accessories include CCD image processing systems or video measurement devices.

- Accuracy compliant with GB/T231.2, ISO 6506-2, and ASTM E10 standards.

Applications

- Used for determining the Brinell hardness of ferrous metals, non-ferrous metals, and bearing alloy materials.

- Broad application range, particularly suitable for soft metal materials and Brinell hardness testing of small components.

Technical Parameter

| Model |

HBS-62.5AT |

|

Measuring Range |

5-650HBW |

|

Test Force |

9.807N,24.52N,49.03N,61.29N,98.07N,153.2N,294.2N,31.125N,612.9N(1kgf,2.5kgf,5kgf,6.25kgf,10kgf,15.625kgf,30kgf,31.25kgf,62.5kgf) |

|

Add The Way |

Electricity and charge |

|

Toward The Way |

Automatic tower |

|

Measurement Method |

Automatic surveying and mapping |

| Maximum height Is Allowed For The Specimen |

200mm |

|

Head Center To Machine Wall Distance |

130mm |

|

Lens Ratio |

5X,10X |

|

Total Magnification |

50X,100X |

|

Hardness Resolution |

0.1HBW |

| Source |

AC 220V,50Hz |

| Outline Dimension |

600*330*700mm |

|

Weight |

75kg |

Standard Configuration Of Accessories

|

XY Testing Bench |

One piece | Xiaoping Test Stage | One piece |

|

Type V Test Stand |

One piece | Φ1、Φ2.5mmCarbented Ball Head | One of Each |

| Φ1、Φ2.5mmSintered Carbide Ball | One of Each | Standard Brinell Hardness Block |

Two pieces |

| 10X Microocular | One piece | Bluetooth Printer |

One piece |

The above is the standard configuration, and the actual configuration is subject to the customized requirements.