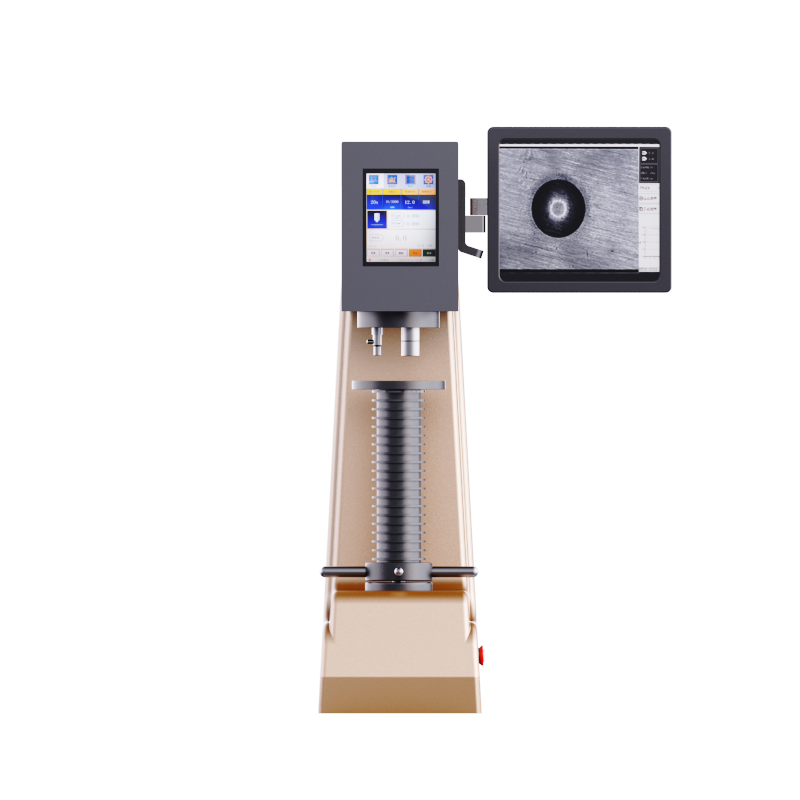

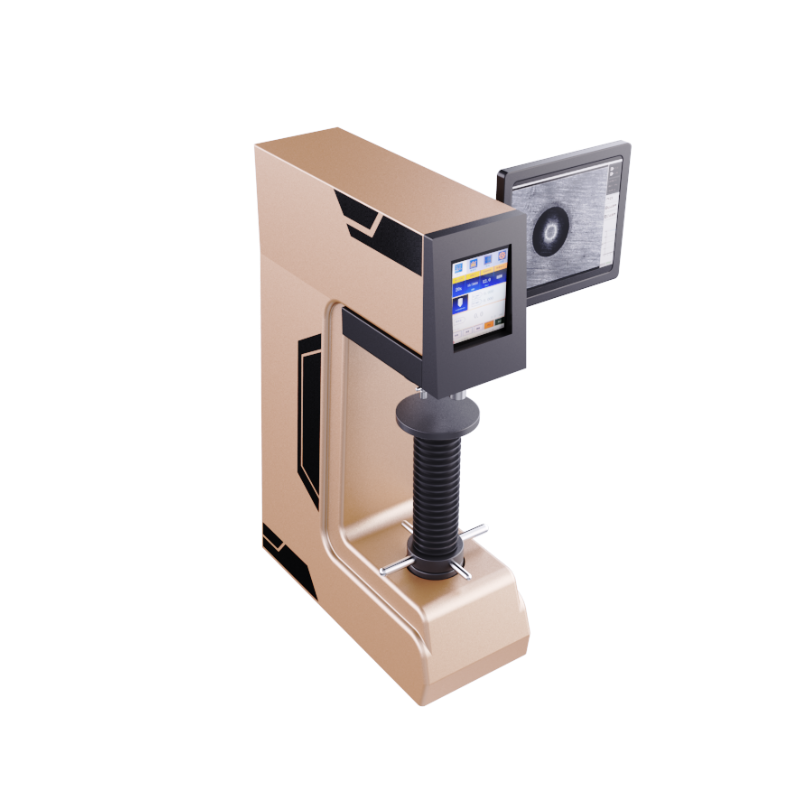

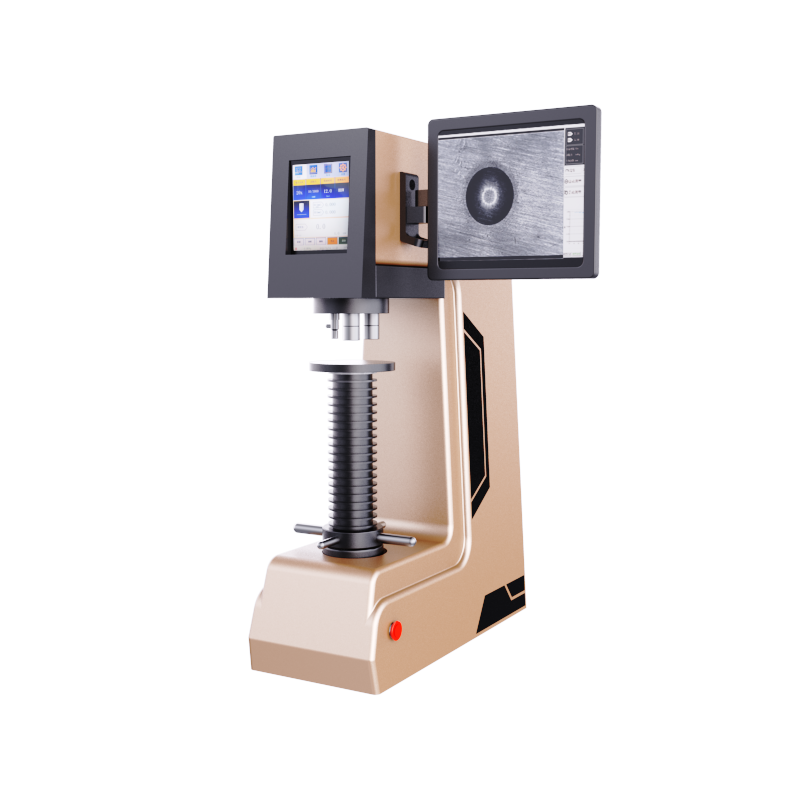

VHBS-3000 AET Visual Brinell Hardness Meter

VHBS-3000 AET visual Brinell hardness meter, with 8-inch touch screen and high-speed ARM processor, intuitive display, human-machine interaction, easy operation, fast database storage, automatic data correction, and provide data line report.

Product Overview

VHBS-3000 AET visual Brinell hardness meter, with 8-inch touch screen and high-speed ARM processor, intuitive display, human-machine interaction, easy operation, fast database storage, automatic data correction, and provide data line report.

Product Presentation

1.Industrial tablet computer is installed on the side of the body, with built-in industrial-grade camera, using CCD image software to process, directly export data and images, complete manual and automatic measurement of the image, convenient and fast;

2.The fuselage uses high quality cast iron primary casting molding, with the car paint treatment process, the shape is round and beautiful;

3.Configuration of automatic tower function, automatic switch between the pressure head and lens, more convenient to use;

4.The maximum and minimum value of the hardness value can be set. When the test value exceeds the set range, send out an alarm sound;

5.With the function of software hardness value correction, you can directly correct the hardness value within a certain range;

6.With the function of database, the test data is automatically saved in groups, each group can save 10 data, and more than 2,000 data can be saved;

7.With the hardness value curve display function, intuitively display the change of hardness value;

8.Can automatically conduct the unit conversion of the full hardness ruler;

9.Electronic closed-loop control and applied test force, fully realize the automatic operation of load adding, retention and unloading;

10.Equipped with HD optical double objective, it can measure the indentation of different diameters under different standard test forces;

11.And can output data through RS232, USB (optional) interface;

12.The accuracy meets GB / T231.2, ISO6506-2 and American ASTM E10 standards.

Applied Range

- Determination the brinell hardness of ferrous metal, non-ferrous metal and bearing alloy materials;

- 2.Hard cast steel, aluminum alloy, copper alloy, malleable castings, soft steel, tempered steel, annealed steel, bearing steel, etc.

Technical Parameter

|

Model |

VHBS-3000AET |

|

Measuring Range |

5-650HBW |

|

Test Force |

612.9N,980.7N,1225.9N,1838.8N,2451.8N,4903.5N,7355.3N,9807N,14710.5N,29421N

(62.5kgf,100kgf,125kgf,187.5kgf,250kgf,500kgf,750kgf,1000kgf,1500kgf,3000kgf) |

| Add The Way |

Electricity and charge |

| Toward The Way |

Automatic tower |

| Test Method |

Automatic surveying and mapping |

|

Maximum Height Is Allowed For The Specimen |

260mm |

|

Head Center To Machine Wall Distance |

165mm |

| Save The Time |

1-99s |

| Vector Magnification |

1X,2X |

|

Total Magnification |

20X,40X |

|

Hardness Resolution |

0.1HBW |

|

Minimum Measurement Unit |

0.625μm |

|

Source |

AC 220V,50Hz |

| Outline Dimension |

700*268*930mm |

| Camera Resolution |

300W pixels |

| The CCD Measurement Method |

Automatic and manual |

| Weight |

160kg |

Annex Standard Configuration

|

Large Flat Workbench |

One piece | V-shaped Workbench | One piece |

|

φ2.5,φ5,φ10mmCarbented Ball Head |

One of each | φ2.5,φ5,φ10mmHard Alloy Steel Ball |

One of each |

| Standard Brinell Hardness Block | Two pieces | Industrial-grade Tablets |

Two pieces |

The above is the standard configuration. Actual configuration may vary based on custom requirements.