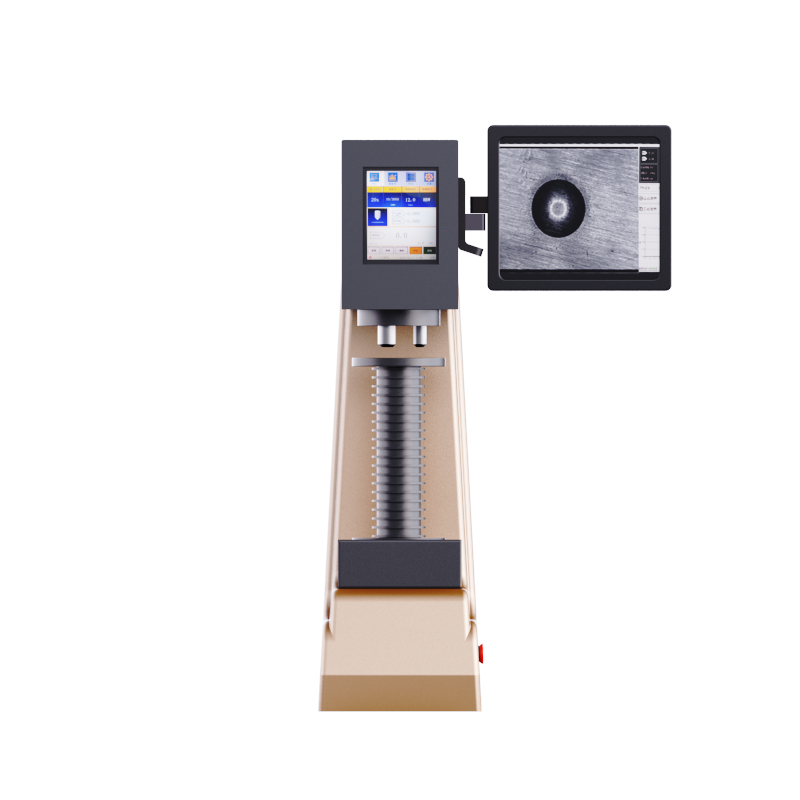

ZVHBS-3000 AET Visual Fully Automatic Brinell Hardness Meter

The ZVHBS-3000AET vision fully automatic Brinell hardness tester is equipped with an 8-inch touchscreen and a high-speed ARM processor, providing intuitive display, user-friendly interaction, and simple operation. It offers fast processing speed, extensive database storage, automatic data correction, and provides data trend line reports.

Product Brief Description

- Automatic Z-axis lifting

- Auto loading, dwell, and unloading

- Automatic turret rotation, auto-focusing

- CCD automatic indentation capture and measurement

- One-button operation for convenience

Product Overview

The ZVHBS-3000AET vision fully automatic brinell hardness tester is equipped with an 8-inch touchscreen and a high-speed ARM processor, providing intuitive display, user-friendly interaction, and simple operation. It offers fast processing speed, extensive database storage, automatic data correction, and provides data trend line reports.

Product Introduction

- Regardless of the size, position, or distance of the specimen from the indenter, the worktable can automatically lift, load, and measure the Brinell hardness of the workpiece.

- The industrial tablet PC and industrial-grade camera are installed on the side of the machine body, utilizing CCD image software processing to directly export data and images, facilitating both manual and automatic image measurement.

- The machine body is cast in high-quality cast iron in a single molding process, complemented by automotive paint processing, ensuring a sleek and attractive appearance.

- Equipped with an automatic turret function, enabling automatic switching between the indenter and lens for enhanced user convenience.

- Maximum and minimum hardness values can be set; when the test value exceeds the set range, an alarm sound is triggered.

- Features software hardness value correction, allowing direct correction of the hardness value within a specific range.

- Includes a database function for automatic grouping and storage of test data, with each group capable of storing 10 data sets, supporting storage of over 2000 data points.

- Offers hardness value curve display, visually demonstrating changes in hardness values.

- Capable of automatic unit conversion for the entire hardness scale.

- Implements electronic closed-loop control for applying test force, fully automating loading, dwelling, and unloading.

- Equipped with high-definition dual eyepieces for measuring indentation diameters under standard test forces ranging from 31.25 to 3000kgf.

- Provides data output through RS232, USB interfaces (optional).

- Accuracy compliant with GB/T231.2, ISO6506-2, and ASTM E10 standards.

Application Range

- Measuring the Brinell hardness of ferrous metals, non-ferrous metals, and bearing alloy materials.

- Suitable for hard cast steel, aluminum alloys, copper alloys, malleable castings, mild steel, quenched steel, annealed steel, bearing steel, and more.

Technical Specifications

|

Model |

ZVHBS-3000AET |

|

Measurement Range |

5-650HBW |

| Test Forces |

306.25(optional configuration)612.9、980.7、1225.9、1838.8、2451.8、4903.5、7355.3、9807、14710.5、29421N(31.25、62.5、100、125、187.5、250、500、750、1000、1500、3000kgf) |

|

Maximum Permissible Height Of The Test Specimen |

260mm |

| Distance From Indenter Center To Machine Wall |

150mm |

| Dwell Time |

1-99s(adjustable) |

|

Objective Lens Magnifications |

1X,2X |

|

Turret |

3 positions – 1 indenter (replaceable), 2 automatic turret for lenses |

|

Total Magnification |

20X, 40X |

|

Hardness Resolution |

0.1HBW |

| Minimum Measuring Unit |

0.625μm |

| Power Supply |

AC 220V,50Hz |

| Dimensions |

700*268*930mm |

| Camera Resolution |

500W pixels |

|

CCD Measurement Modes |

Automatic and manual |

| Weight |

160kg |

Standard Configuration Of Accessories

|

Large Flat Workbench |

One piece | V-shaped Workbench |

One piece |

|

Hard AlloyBallIndenters:φ2.5mm, φ5mm, φ10mm |

One of each | Hardened Steel Balls:φ2.5mm, φ5mm, φ10mm | Two of each |

| Standard Brinell Hardness Blocks | Three pieces | Industrial-grade Tablet PC |

One unit |

The above is the standard configuration. Actual products are subject to physical objects.