Table of Contents

Importance of Regular hardness tester Calibration

hardness testers are essential tools used in various industries to measure the hardness of materials. These devices play a crucial role in ensuring the quality and reliability of products, as hardness is often a critical factor in determining the performance and durability of materials. To ensure the accuracy and reliability of hardness test results, regular calibration of hardness testers is essential.

Calibration is the process of comparing the measurements of a device to a known standard to determine its accuracy. In the case of hardness testers, calibration involves verifying that the device is providing accurate and consistent hardness measurements. This is important because even small errors in hardness measurements can have significant consequences, leading to faulty products, wasted materials, and potential safety hazards.

Regular calibration of hardness testers is necessary to maintain the accuracy and reliability of hardness measurements. Over time, factors such as wear and tear, environmental conditions, and operator error can affect the performance of hardness testers, leading to inaccuracies in hardness measurements. By calibrating hardness testers regularly, these issues can be identified and corrected, ensuring that hardness measurements are accurate and reliable.

Calibration also helps to ensure that hardness testers are operating within acceptable tolerances. Manufacturers of hardness testers typically provide specifications for the acceptable range of hardness measurements that the device can provide. By calibrating hardness testers regularly, operators can verify that the device is operating within these tolerances, providing confidence in the accuracy of hardness measurements.

In addition to ensuring the accuracy and reliability of hardness measurements, regular calibration of hardness testers can also help to extend the lifespan of the device. By identifying and correcting issues early on, calibration can prevent more serious problems from developing, reducing the risk of costly repairs or replacements.

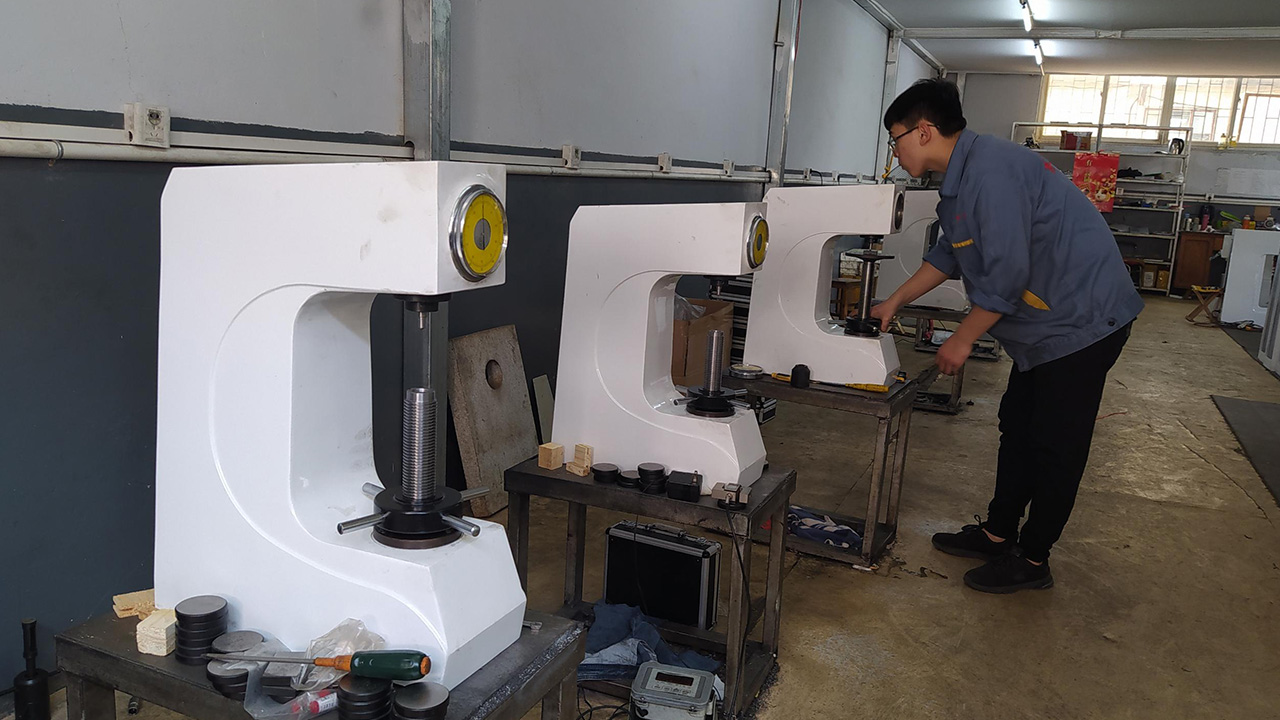

When it comes to hardness tester calibration, Chinese manufacturers are known for their high-quality, yet affordable calibration services. Chinese manufacturers offer a wide range of calibration services for hardness testers, including on-site calibration, off-site calibration, and calibration training. These services are typically performed by highly trained technicians using state-of-the-art equipment and techniques to ensure the accuracy and reliability of hardness measurements.

Chinese manufacturers also offer competitive pricing for hardness tester calibration services, making them an attractive option for businesses looking to maintain the accuracy and reliability of their hardness testers without breaking the bank. By choosing a Chinese manufacturer for hardness tester calibration, businesses can benefit from high-quality calibration services at a fraction of the cost of other providers.

In conclusion, regular calibration of hardness testers is essential for ensuring the accuracy and reliability of hardness measurements. By calibrating hardness testers regularly, businesses can identify and correct issues early on, maintain the accuracy of hardness measurements, and extend the lifespan of the device. Chinese manufacturers offer high-quality, yet affordable calibration services for hardness testers, making them a competitive option for businesses looking to maintain the accuracy and reliability of their hardness testers.

Comparing Chinese High-Grade and Cheapest Competitive Manufacturer Hardness Testers

When it comes to hardness testers, accuracy and reliability are crucial factors to consider. Calibration plays a significant role in ensuring that these instruments provide precise and consistent results. In the market, there are various manufacturers offering hardness testers, with Chinese high-grade and cheapest competitive manufacturers being popular choices. In this article, we will compare the calibration processes of these two types of manufacturers to help you make an informed decision when selecting a hardness tester for your needs.

Chinese high-grade manufacturers are known for producing quality instruments that meet international standards. These manufacturers invest in advanced technology and quality control measures to ensure that their hardness testers are accurate and reliable. Calibration is a critical step in the production process of these instruments, as it determines the accuracy of the readings they provide.

The calibration process for Chinese high-grade hardness testers typically involves using certified reference blocks with known hardness values. These reference blocks are used to calibrate the instrument and ensure that it is providing accurate readings. The calibration process is usually performed by trained technicians who follow strict procedures to ensure that the instrument meets the required standards.

On the other hand, cheapest competitive manufacturers may not invest as much in technology and quality control measures. As a result, the calibration process for their hardness testers may not be as rigorous or accurate. These manufacturers may use less reliable methods for calibration, which can lead to inconsistencies in the readings provided by their instruments.

When comparing Chinese high-grade and cheapest competitive manufacturers, it is essential to consider the level of accuracy and reliability that you require from a hardness tester. If you need precise and consistent results, investing in a Chinese high-grade hardness tester may be the best option for you. These instruments are designed to meet international standards and undergo rigorous calibration processes to ensure their accuracy.

However, if you are working on a tight budget and do not require the highest level of accuracy, a hardness tester from a cheapest competitive manufacturer may be a suitable option for you. While these instruments may not offer the same level of accuracy as Chinese high-grade hardness testers, they can still provide reliable results for many applications.

In conclusion, when choosing a hardness tester, it is essential to consider the calibration process of the manufacturer. Chinese high-grade manufacturers invest in advanced technology and quality control measures to ensure the accuracy and reliability of their instruments. Cheapest competitive manufacturers may not offer the same level of accuracy, but their hardness testers can still provide reliable results for many applications. Ultimately, the choice between these two types of manufacturers will depend on your specific needs and budget constraints.