Benefits of Using a hardness tester for Quality Control in China

Quality control is a crucial aspect of manufacturing processes in China, as it ensures that products meet the required standards and specifications. One of the key tools used in quality control is a hardness tester, which measures the hardness of materials and helps to assess their mechanical properties. In China, there are many suppliers of hardness testers, but finding a high-quality product at the lowest price can be a challenge. However, there are certain benefits to using a hardness tester for quality control in China that make it a worthwhile investment for manufacturers.

One of the main benefits of using a hardness tester for quality control in China is the ability to accurately assess the hardness of materials. Hardness is an important mechanical property that can affect the performance and durability of a product. By using a hardness tester, manufacturers can ensure that materials meet the required hardness levels, which in turn can help to prevent defects and failures in the final product. This can ultimately lead to cost savings and improved product quality.

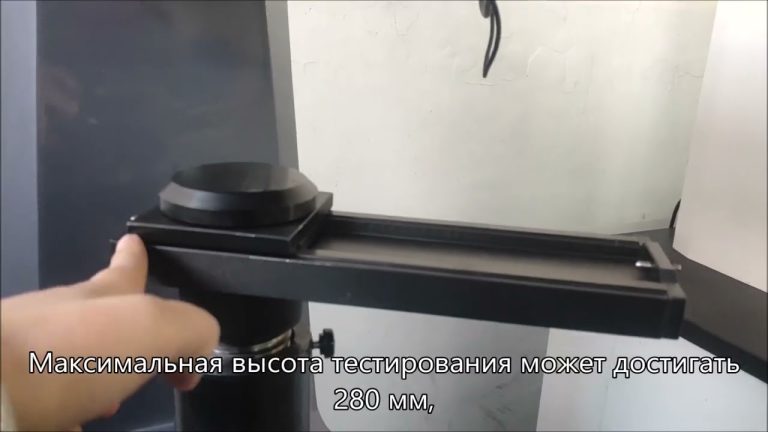

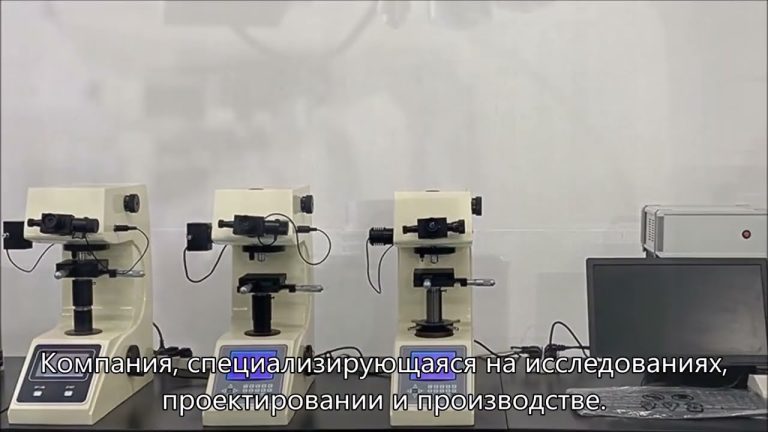

Another benefit of using a hardness tester for quality control in China is the ability to quickly and easily test a wide range of materials. Hardness testers are versatile tools that can be used to test metals, plastics, ceramics, and other materials. This flexibility allows manufacturers to use a single hardness tester for a variety of applications, which can help to streamline the quality control process and improve efficiency. Additionally, many hardness testers in China come with advanced features such as automatic testing and data logging, which further enhance their usability and accuracy.

In addition to accuracy and versatility, using a hardness tester for quality control in China can also help manufacturers comply with industry standards and regulations. Many industries have specific hardness requirements for their products, and using a hardness tester can help manufacturers ensure that their products meet these standards. This can be especially important for manufacturers in China who export their products to international markets, as compliance with industry standards can help to build trust and credibility with customers.

Furthermore, using a hardness tester for quality control in China can help manufacturers identify and address potential issues early in the production process. By testing materials for hardness before they are used in the final product, manufacturers can identify any inconsistencies or defects that may affect the quality of the finished product. This proactive approach to quality control can help to prevent costly rework and recalls, and ultimately improve customer satisfaction.

Overall, using a hardness tester for quality control in China offers a range of benefits that can help manufacturers improve product quality, efficiency, and compliance with industry standards. While finding a high-quality hardness tester at the lowest price may require some research and comparison, the investment is likely to pay off in the long run through improved product quality and customer satisfaction. By leveraging the benefits of hardness testing, manufacturers in China can enhance their quality control processes and gain a competitive edge in the global market.