No products were found matching your selection.

Other Related Products

-

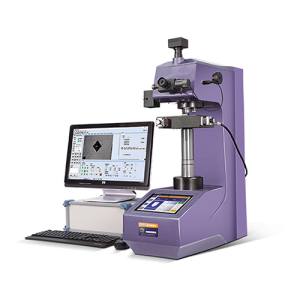

The HB-3000ET touch screen electronic Brinell hardness tester can display hardness values on an LCD screen and allows for the display and setting of testing scales, test forces, indenter types, hold times, and unit conversions.

-

1.ABS shell and stainless steel standard parts, reliable and durable.

2.The speed of grinding plate and grinding head can be adjusted without pole.

3.The rotation direction of the grinding wheel can be selected arbitrarily.

4.Sampling preparation pressure and time can be set.

5.1-6 samples can be processed simultaneously.

-

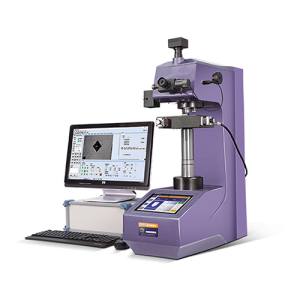

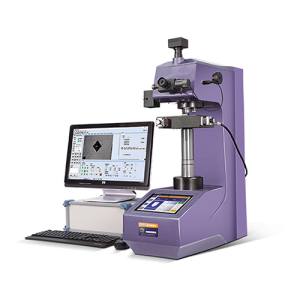

This hardness tester adopts advanced design concepts. Advanced technologies in mechanical, electrical, and optical aspects are employed in the field of hardness testers today. The test results are precise, with strong repeatability. Equipped with Brinell hardness image processing system, it offers high automation, low labor intensity for operators, minimal human error, and a novel and appealing appearance. It is one of the most advanced Brinell hardness testers domestically and can fully replace similar imported products. It can quickly and accurately measure the Brinell hardness value of the test piece.

-

This mill is a desktop double-disc double-control grinding machine, suitable for rough grinding, fine grinding and polishing of gold test samples.

-

- Automatic control operation of touch screen

- Large volume cutting room, fully enclosed design

- Pure stainless steel workbench, corrosion resistance

- Fast fixture, fast clamp

- The operation panel adopts 24V safe voltage

-

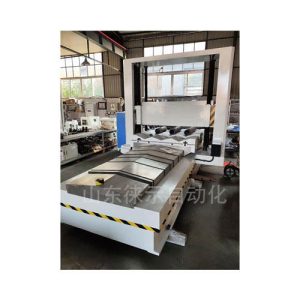

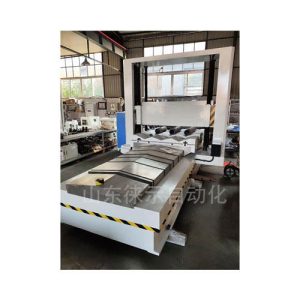

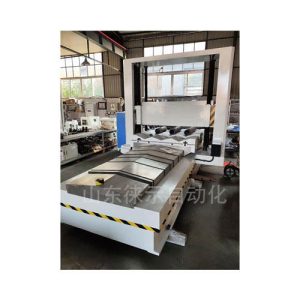

The ZHRSJ-150B fully automatic large-sized digital Rockwell Hardness Tester features an 8-inch touchscreen and a high-speed ARM processor, providing intuitive display, user-friendly human-machine interaction, and simple operation. It offers fast computation speed, extensive database storage, automatic data correction, and generates data trend line reports.

-

ZXQ-2Y automatic inlay machine is an advanced hydraulic water-cooled type automatic sample inlay equipment, unique cold and hot separation design, the sample inlay time to 6 minutes, greatly improve the work efficiency, inlay process controlled by automatic program, implements the heating, pressure, pressure, cooling, pressure discharge inlay process of one-key operation, no operator unattended, automatically complete sample inlay.

-

- Automatic loading, retention and unloading

- Autofocus, automatic measurement

- Workbench XYZ axis is fully automatic operation

- With a panoramic scanning function

- 17 kinds of path planning, free setting

-

- Z-axis automatic lifting

- Automatic loading, dwell, and unloading

- Electronic closed-loop control for applying test force

- Covers 30 Rockwell scales

- One-button operation for convenience and speed