Table of Contents

Advantages of Using Shore hardness testers in Quality Control Processes

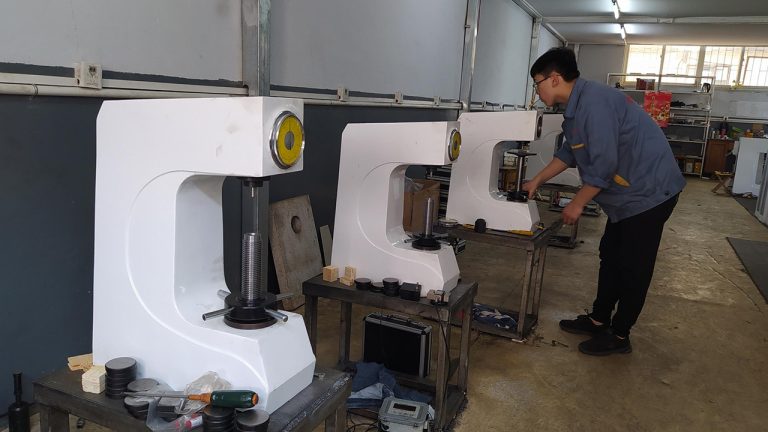

Shore hardness testers are essential tools in quality control processes across various industries. These devices are used to measure the hardness of materials, providing valuable information about their durability, flexibility, and overall quality. In the manufacturing sector, shore hardness testers play a crucial role in ensuring that products meet the required standards and specifications.

One of the key advantages of using shore hardness testers is their ability to provide accurate and reliable measurements. These devices are designed to measure the resistance of a material to indentation, giving manufacturers a clear indication of its hardness. By using shore hardness testers, companies can ensure that their products are of consistent quality and meet the necessary performance requirements.

In addition to providing accurate measurements, shore hardness testers are also easy to use and operate. These devices are typically portable and user-friendly, allowing operators to quickly and efficiently test materials on the production line. This ease of use makes shore hardness testers a valuable tool for quality control processes, as they can be easily integrated into existing workflows without causing disruptions.

Furthermore, shore hardness testers are versatile tools that can be used to test a wide range of materials, including plastics, rubber, and metals. This versatility makes shore hardness testers a cost-effective solution for manufacturers, as they can be used to test multiple materials with a single device. By investing in a shore hardness tester, companies can streamline their quality control processes and ensure that all materials meet the necessary hardness requirements.

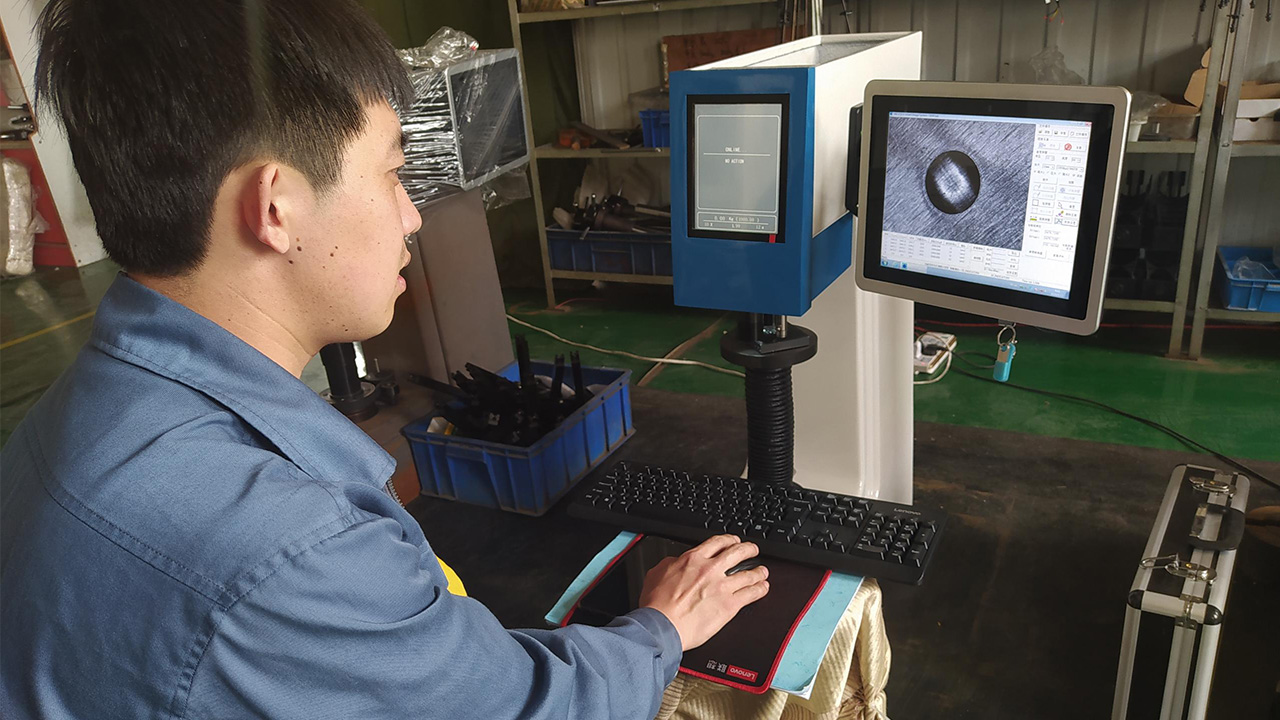

Another advantage of using shore hardness testers is their ability to detect inconsistencies and defects in materials. By measuring the hardness of a material, shore hardness testers can identify areas of weakness or inconsistency that may affect the overall quality of a product. This information allows manufacturers to make necessary adjustments to their production processes and ensure that all products meet the required standards.

In conclusion, shore hardness testers are essential tools for quality control processes in various industries. These devices provide accurate and reliable measurements, are easy to use and operate, and can test a wide range of materials. By investing in a shore hardness tester, companies can improve the quality of their products, streamline their production processes, and ensure that all materials meet the necessary hardness requirements. Shore hardness testers are a valuable asset for manufacturers looking to maintain high standards of quality and consistency in their products.

How to Choose the Right Shore Hardness Tester for Your Business

When it comes to testing the hardness of materials, a shore hardness tester is an essential tool for many industries. Whether you work in manufacturing, quality control, or research and development, having the right shore hardness tester can make a significant difference in the accuracy and efficiency of your work. With so many options available on the market, it can be overwhelming to choose the right shore hardness tester for your business. However, if you are looking for a high-grade shore hardness tester at the lowest price, a Chinese wholesaler may be the best option for you.

Chinese wholesalers are known for offering high-quality products at competitive prices, making them a popular choice for businesses looking to save money without compromising on quality. When it comes to shore hardness testers, Chinese wholesalers offer a wide range of options to suit different needs and budgets. From handheld testers to benchtop models, you can find a variety of shore hardness testers to choose from.

One of the key factors to consider when choosing a shore hardness tester is the type of material you will be testing. Different shore hardness testers are designed to measure the hardness of specific materials, so it is essential to choose a tester that is suitable for the materials you work with. For example, if you work with rubber or plastics, you will need a shore hardness tester that is specifically designed for these materials.

In addition to the type of material, you should also consider the hardness range you need to measure. Shore hardness testers are available in different scales, such as Shore A, Shore D, and Shore OO, each designed to measure different hardness ranges. It is essential to choose a tester that can accurately measure the hardness of the materials you work with.

When purchasing a shore hardness tester from a Chinese wholesaler, it is essential to ensure that the product meets international quality standards. Look for certifications such as CE or ISO to ensure that the tester meets the necessary requirements for accuracy and reliability. Additionally, read reviews from other customers to get an idea of the quality and performance of the tester before making a purchase.

Another important factor to consider when choosing a shore hardness tester is the features and specifications of the product. Look for testers that offer features such as digital displays, automatic calibration, and data storage capabilities to make your work more efficient and accurate. Additionally, consider the size and weight of the tester, as well as any additional accessories that may be included with the product.

In conclusion, choosing the right shore hardness tester for your business is essential for ensuring accurate and reliable hardness measurements. Chinese wholesalers offer a wide range of high-grade shore hardness testers at competitive prices, making them a great option for businesses looking to save money without compromising on quality. By considering factors such as the type of material, hardness range, certifications, and features of the tester, you can find the perfect shore hardness tester to meet your business needs.