It seems we can’t find what you’re looking for. Perhaps searching can help.

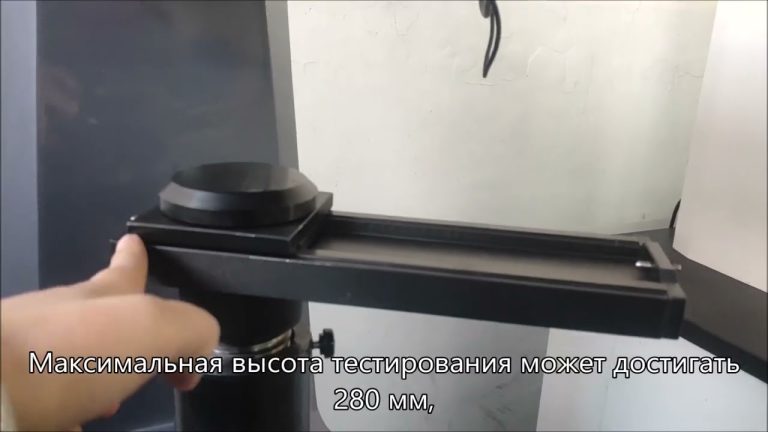

detroit hardness tester China high quality cheap Make

Exploring the Benefits of Using Detroit hardness testers Detroit hardness testers are a crucial tool in the field of material testing, providing accurate and reliable measurements of a material’s hardness. These testers are widely used in various industries, including manufacturing, automotive, aerospace, and construction. In recent years, China has emerged…