It seems we can’t find what you’re looking for. Perhaps searching can help.

hardness test ndt company

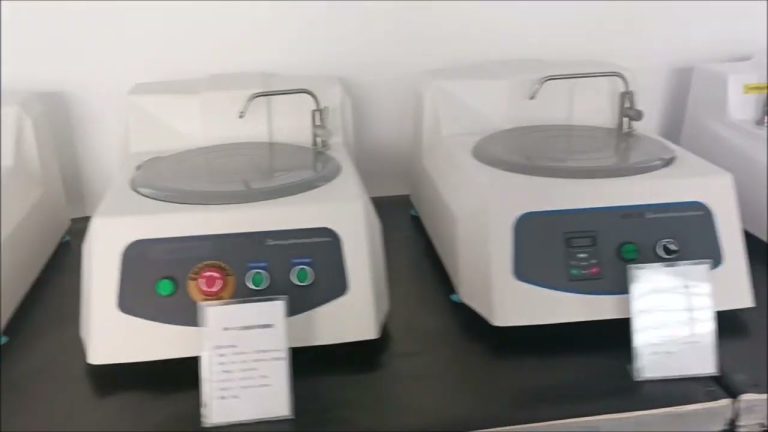

Benefits of hardness testing for NDT Companies Hardness testing is a crucial process for non-destructive testing (NDT) companies. It involves measuring the resistance of a material to deformation, which can provide valuable insights into its mechanical properties. By conducting hardness tests, NDT companies can ensure the quality and reliability of…