It seems we can’t find what you’re looking for. Perhaps searching can help.

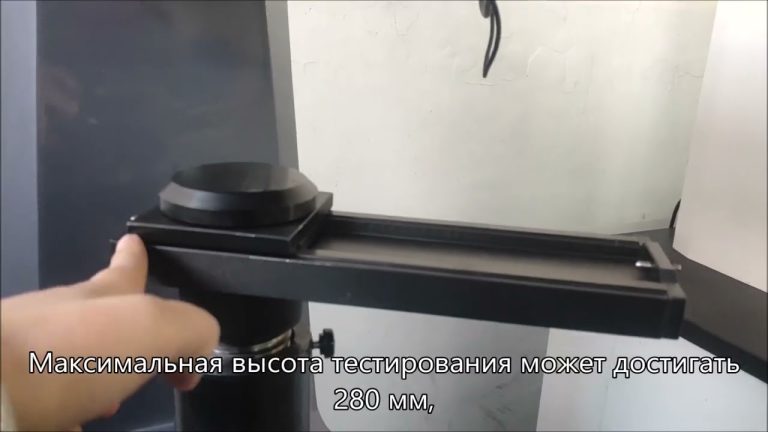

mic 10 hardness tester China good company

Benefits of Using a Mic hardness tester in Material Testing Material testing is a crucial process in various industries, as it helps ensure the quality and reliability of products. One of the key tools used in material testing is a hardness tester, which measures the resistance of a material to…