It seems we can’t find what you’re looking for. Perhaps searching can help.

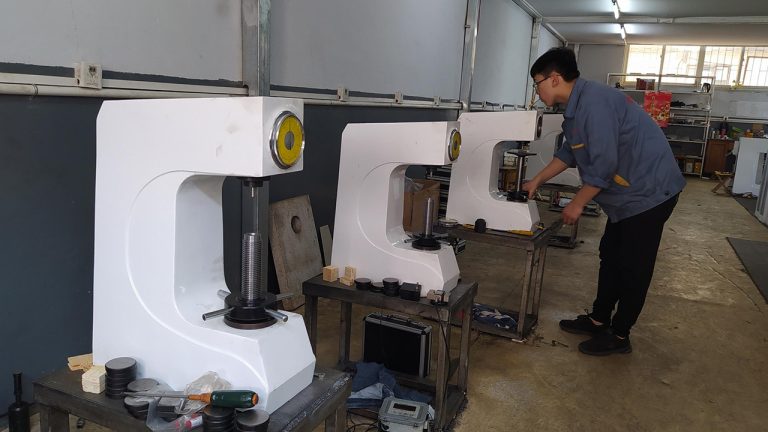

hrc hardness tester China best Exporter

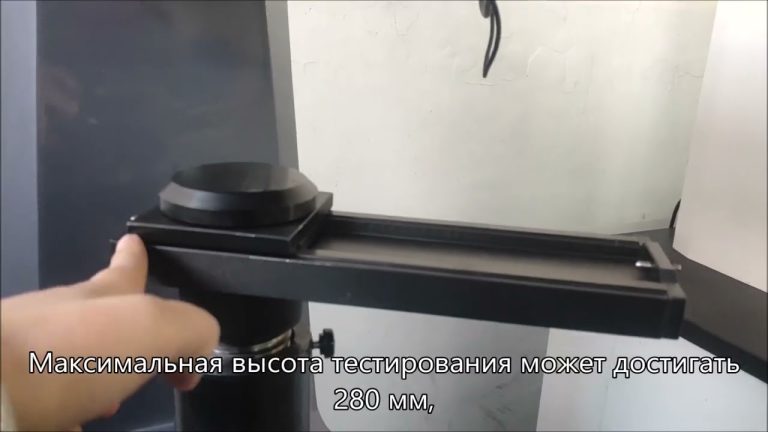

How to Choose the Best HRC hardness tester for Your Needs When it comes to testing the hardness of materials, having the right equipment is essential. HRC hardness testers are commonly used in various industries to determine the hardness of metals and alloys. If you are in the market for…