Table of Contents

Benefits of Using hardness testers in Pharmaceutical Manufacturing

Hardness testers play a crucial role in the pharmaceutical manufacturing process, ensuring that tablets and capsules meet the required quality standards. These devices are used to measure the hardness of pharmaceutical products, providing valuable data that can help manufacturers maintain consistency and quality in their production processes.

One of the key benefits of using hardness testers in pharmaceutical manufacturing is the ability to ensure product quality and consistency. By measuring the hardness of tablets and capsules, manufacturers can identify any variations in the manufacturing process that may affect the final product. This allows them to make adjustments as needed to ensure that all products meet the required specifications.

In addition to ensuring product quality, hardness testers also help manufacturers comply with regulatory requirements. The pharmaceutical industry is highly regulated, with strict guidelines in place to ensure the safety and efficacy of pharmaceutical products. By using hardness testers to monitor the quality of their products, manufacturers can demonstrate compliance with these regulations and avoid costly fines or recalls.

Another benefit of using hardness testers in pharmaceutical manufacturing is the ability to improve efficiency and reduce waste. By accurately measuring the hardness of tablets and capsules, manufacturers can identify any issues in the production process that may be causing defects or inconsistencies. This allows them to make adjustments in real-time, reducing the amount of waste produced and improving overall efficiency.

Furthermore, hardness testers can also help manufacturers save time and money by streamlining the quality control process. Instead of relying on manual testing methods, which can be time-consuming and prone to human error, hardness testers provide fast and accurate results that can be easily recorded and analyzed. This allows manufacturers to quickly identify any issues and take corrective action, reducing the risk of product defects and ensuring that all products meet the required quality standards.

Overall, the use of hardness testers in pharmaceutical manufacturing offers a wide range of benefits, from ensuring product quality and compliance with regulations to improving efficiency and reducing waste. These devices play a crucial role in the production process, providing manufacturers with valuable data that can help them maintain consistency and quality in their products.

In conclusion, hardness testers are an essential tool for pharmaceutical manufacturers looking to ensure the quality and consistency of their products. By using these devices, manufacturers can monitor the hardness of tablets and capsules, identify any issues in the production process, and make adjustments as needed to maintain product quality. With the ability to improve efficiency, reduce waste, and streamline the quality control process, hardness testers offer a wide range of benefits that can help manufacturers achieve success in the highly regulated pharmaceutical industry.

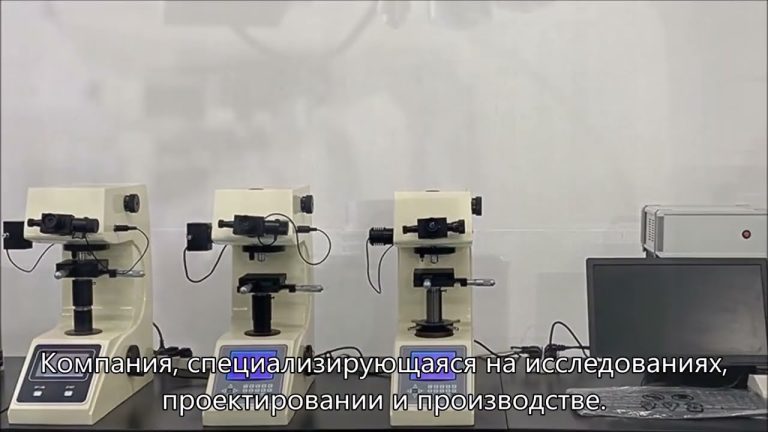

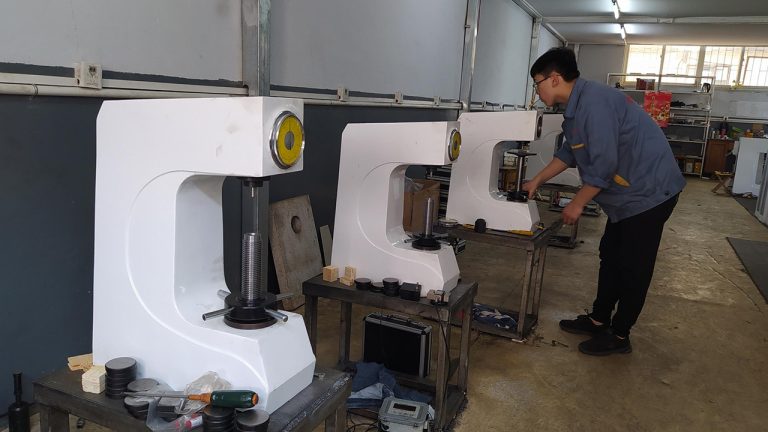

Comparison of Different Hardness Testers from Chinese High-Grade Exporters

hardness testing is a critical process in the pharmaceutical industry to ensure the quality and consistency of tablets and capsules. Chinese high-grade exporters offer a variety of hardness testers that are reliable and accurate for pharmaceutical manufacturers. In this article, we will compare different hardness testers from Chinese high-grade exporters to help you make an informed decision for your pharmaceutical production needs.

One of the top hardness testers from Chinese high-grade exporters is the YD-2 Tablet hardness tester. This tester is designed with precision and accuracy in mind, providing pharmaceutical manufacturers with reliable results. The YD-2 Tablet Hardness Tester is easy to use and offers a wide range of testing capabilities, making it a versatile option for pharmaceutical production facilities.

Another popular hardness tester from Chinese high-grade exporters is the YD-3 Tablet Hardness Tester. This tester is known for its durability and reliability, making it a top choice for pharmaceutical manufacturers. The YD-3 Tablet Hardness Tester is designed to withstand the rigors of daily use in a pharmaceutical production environment, ensuring consistent and accurate results every time.

In addition to the YD-2 and YD-3 Tablet Hardness Testers, Chinese high-grade exporters also offer the YD-4 Tablet Hardness Tester. This tester is designed with advanced technology and features, providing pharmaceutical manufacturers with precise and reliable results. The YD-4 Tablet Hardness Tester is a top-of-the-line option for pharmaceutical production facilities looking for the highest level of accuracy and consistency in their hardness testing.

When comparing different hardness testers from Chinese high-grade exporters, it is important to consider the specific needs of your pharmaceutical production facility. Factors such as testing capabilities, durability, and accuracy should all be taken into account when choosing a hardness tester for your operation. By carefully evaluating the features and benefits of each tester, you can select the best option for your pharmaceutical manufacturing needs.

In conclusion, Chinese high-grade exporters offer a variety of hardness testers that are reliable and accurate for pharmaceutical manufacturers. The YD-2, YD-3, and YD-4 Tablet Hardness Testers are all top options for pharmaceutical production facilities looking for precision and consistency in their hardness testing. By comparing the features and benefits of each tester, you can make an informed decision for your pharmaceutical manufacturing needs. Choose a hardness tester from a Chinese high-grade exporter to ensure the quality and consistency of your tablets and capsules.