No products were found matching your selection.

Other Related Products

-

The ZHRSJ-150B fully automatic large-sized digital Rockwell Hardness Tester features an 8-inch touchscreen and a high-speed ARM processor, providing intuitive display, user-friendly human-machine interaction, and simple operation. It offers fast computation speed, extensive database storage, automatic data correction, and generates data trend line reports.

-

This machine is suitable for cutting the samples of various metal and non-metallic materials to observe the metallographic and lithofacies organization.

-

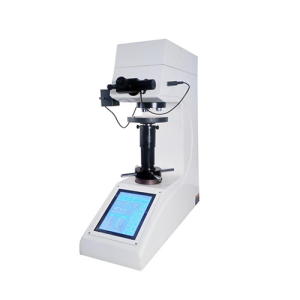

The YHV(S)-5/10/30/50(A)T Touchscreen (Digital) (Automatic Turret) Vickers Hardness Tester utilizes an 8-inch touchscreen and high-speed ARM processor, providing an intuitive display, user-friendly interaction, and straightforward operation. It offers fast computation speed, massive database storage, automatic data correction, and provides data trend line reports.

-

This mill is a desktop double-disc double-control grinding machine, suitable for rough grinding, fine grinding and polishing of gold test samples.

-

The HB-3000ET touch screen electronic Brinell hardness tester can display hardness values on an LCD screen and allows for the display and setting of testing scales, test forces, indenter types, hold times, and unit conversions.

-

The new model HRD-150 electric Rockwell Hardness Tester is controlled by a motor for the loading, holding, and unloading of test force, with the option to select a hold time. It offers convenient, rapid operation without human error, and demonstrates high sensitivity and stability.

-

1.ABS shell and stainless steel standard parts, reliable and durable.

2.The speed of grinding plate and grinding head can be adjusted without pole.

3.The rotation direction of the grinding wheel can be selected arbitrarily.

4.Sampling preparation pressure and time can be set.

5.1-6 samples can be processed simultaneously.

-

MP-3 automatic grinding machine is a single disk desktop machine, which is a new generation of international advanced technology manufacturing according to international standards.

-

The HBS-62.5AT Touch Screen Digital Automatic Turret Low Load Brinell Hardness Tester utilizes an 8-inch touch screen and a high-speed ARM processor, offering intuitive display, user-friendly human-machine interaction, and simple operation. With fast computation speeds, extensive database storage, automatic data correction, and data trend report capabilities.