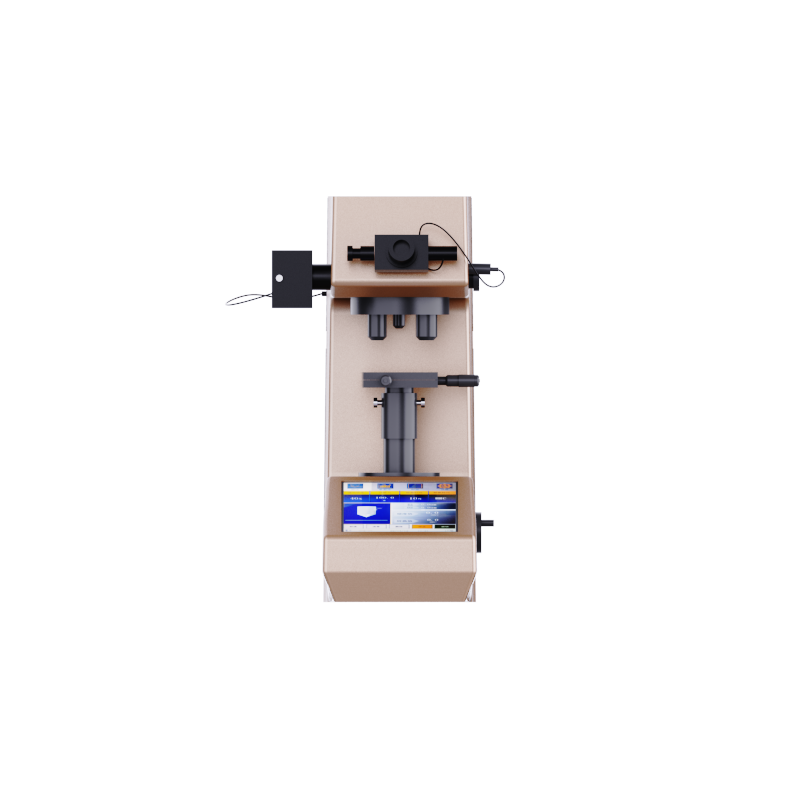

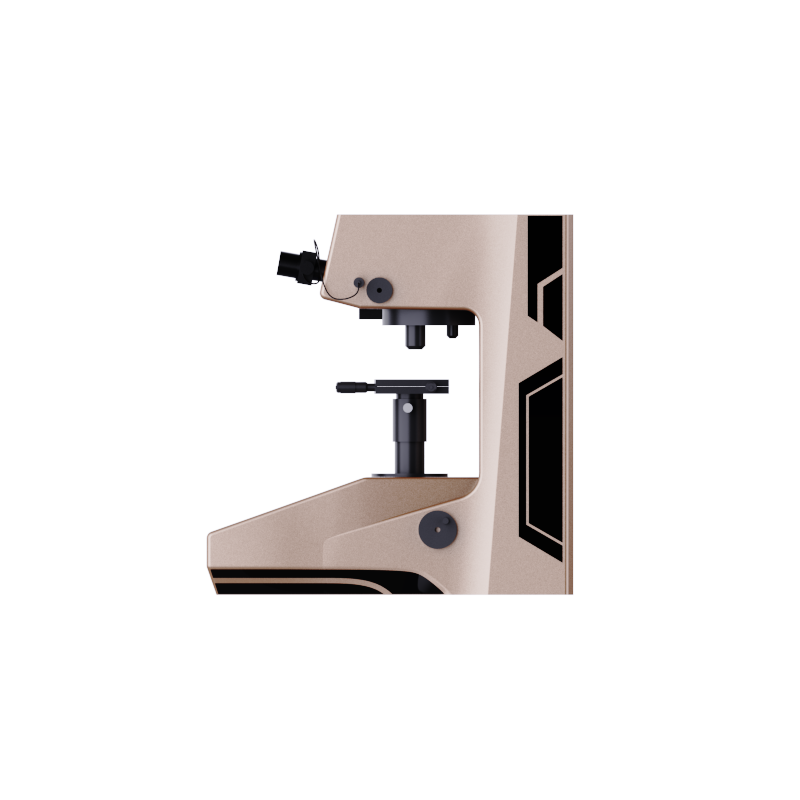

HVS-1000AT Touch Screen Digital Automatic Turret Micro Vickers Hardness Tester

The HVS-1000AT Touch Screen Digital Automatic Turret Micro Vickers Hardness Tester features an 8-inch touch screen and a high-speed ARM processor, providing intuitive display, user-friendly human-computer interaction, and easy operation. It offers fast processing speed, massive database storage, automatic data correction, and provides data line chart reports.

Product Brief Description

- 8-inch touch screen display

- Worm and worm gear lifting, precise positioning

- Automatic loading, holding load, and unloading

- Automatic turret rotation, digital measurement

- Equipped with a database, capable of storing 2000 sets of data

Product Overview

The HVS-1000AT Touch Screen Digital Automatic Turret micro vickers hardness tester features an 8-inch touch screen and a high-speed ARM processor, providing intuitive display, user-friendly human-computer interaction, and easy operation. It offers fast processing speed, massive database storage, automatic data correction, and provides data line chart reports.

Product Introduction

- The machine body is cast in high-quality iron in a single molding process, combined with automotive paint treatment for a sleek and aesthetically pleasing appearance.

- The worm and worm gear lifting system significantly enhances test stability and accuracy, eliminating the need for refocusing after testing.

- Equipped with an automatic turret function, high-definition measurement and observation, a dual objective lens combination, and a high-definition measuring microscope with built-in length encoders enable one-touch measurement of indentation diagonals, effectively reducing manual operation interference and reading errors.

- Convenient CNC system allowing for automatic unit conversion of full hardness scales.

- Capability to set maximum and minimum hardness values; emits an audible alarm when the test value exceeds the set range.

- Features software hardness value correction, allowing direct adjustment of hardness values within a certain range.

- Database feature automatically saves test data in groups, with each group able to store 10 sets of data, totaling more than 2000 data sets.

- Hardness value curve display function offering visual representation of hardness value changes.

- Optional CCD image processing system and Rockwell indenter for Rockwell hardness measurement.

- Equipped with a wireless Bluetooth printer and can output data through RS232, USB (optional) interfaces.

- Accuracy conforms to GB/T4340.2, ISO 6507-2, and ASTM E384 standards.

Scope Of Application

- Ferrous metals, non-ferrous metals, IC wafers, surface coatings, laminated metals;

- Glass, ceramics, agate, gemstones, thin plastics, etc.;

- hardness testing of carbide layers and quenching layers’ depth and gradient.

- Suitable for precision micro-Vickers hardness measurement of parallel planes, small parts, and ultra-thin components.

Technical Specifications

|

Model |

HVS-1000AT |

| Measurement Range |

5-5000HV |

| Test Forces |

0.09807、0.2452、0.4904、0.9807、1.961、2.942、4.904、9.807N(10、25、50、100、200、300、500、1000g) |

|

Data Input Method |

Automatic |

| Turret Mode |

Automatic |

|

A: Automatic Turret S: Digital Measurement And Mapping Users Can Select Configurations According To Their Specific Functional Needs.

|

|

|

Maximum Allowable Height Of The Test Piece |

120mm |

|

Distance From Indenter Center To Machine Wall |

110mm |

|

XY Worktable Size |

100*100mm |

| XY Worktable Travel |

25*25mm |

| XY Worktable Minimum Unit |

0.01mm |

|

Lens Magnifications |

10×,40× |

|

Magnification |

100×,400× |

|

Minimum Step Distance |

0.025μm |

| Hardness Resolution |

0.1HV |

| Power Supply |

AC 220V,50Hz |

|

Dimensions |

540*300*520mm |

| Weight |

45kg |

Standard Configuration of Accessories

|

XY Worktable |

One piece | Fine Shaft Test Stand | One piece |

|

Thin Sheet Test Stand |

One piece | Small Flat Jaw Test Stand | One piece |

|

Large V-block |

One piece | Small V-block |

One piece |

| Diamond Vickers Indenter | One piece | Standard Microhardness Blocks |

Two pieces |

| Printer |

One unit |