It seems we can’t find what you’re looking for. Perhaps searching can help.

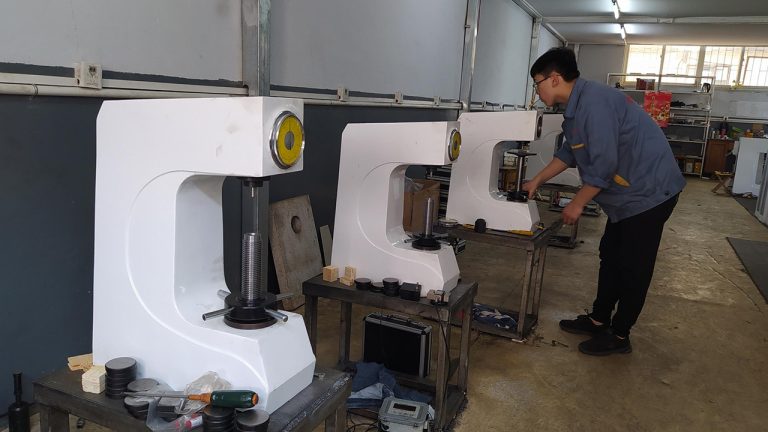

Types of Hardness Testers

The common types of hardness testers mainly include the following: In the mechanical manufacturing industry, different types of hardness testers may be selected according to different parts and process requirements. For large rough parts, the brinell hardness tester may be used for initial testing first, while for precision parts that…