A metal hardness tester is an instrument used to measure the hardness of metal materials.

Hardness is an important indicator for measuring the ability of metal materials to resist local deformation, especially plastic deformation, indentation, or scratch. The metal hardness tester applies a certain pressure, impact force, or other forms of action to the metal material through specific testing methods and principles, and then evaluates the hardness value of the metal based on parameters such as the size, depth, and rebound height of the resulting indentation.

Common types of metal hardness testers include brinell hardness testers, rockwell hardness testers, Vickers hardness testers, Leeb hardness testers, etc.

The brinell hardness tester determines hardness by measuring the diameter of the indentation and is suitable for measuring relatively soft metal materials. For example, it is used to measure unquenched steel.

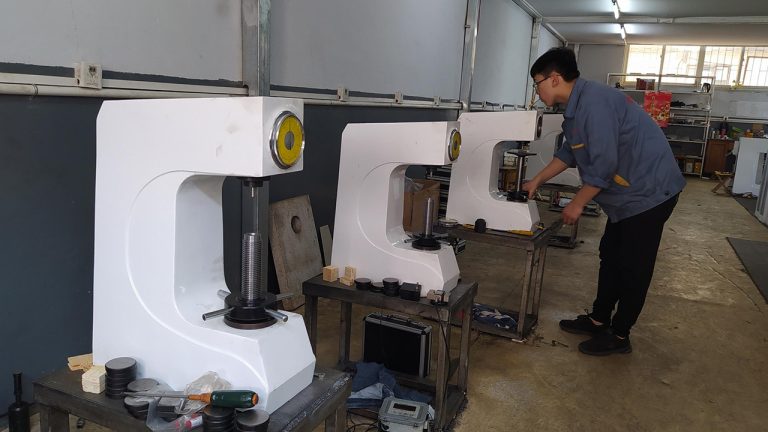

The rockwell hardness tester obtains the hardness value by measuring the depth of the indentation and has a wide range of applications. For instance, it can be used to measure quenched steel parts.

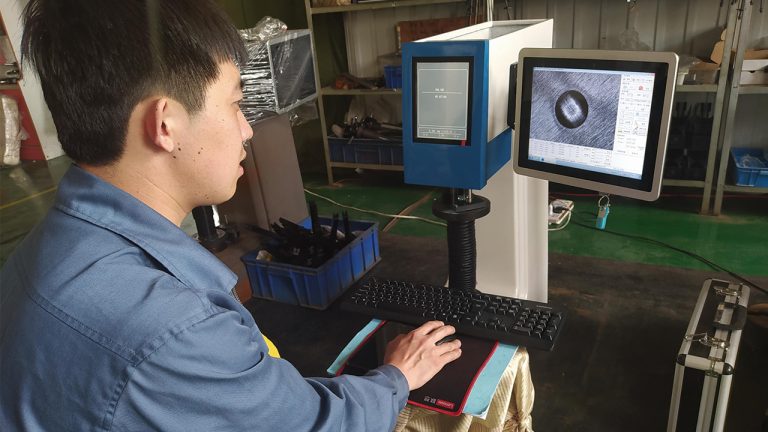

The vickers hardness tester uses a diamond pyramid indenter to press into the material surface and calculates the hardness by measuring the diagonal length of the indentation. It is suitable for measuring thin parts and surface hardened layers.

The Leeb hardness tester is a portable hardness tester that calculates the hardness based on the ratio of the rebound speed to the impact speed after the impact body strikes the metal surface. It is often used for on-site hardness testing of large workpieces and components that are not easy to disassemble.

Metal hardness testers have wide applications in fields such as materials science, mechanical manufacturing, and quality inspection. They can help determine the performance and quality of metal materials and provide important basis for material selection, the formulation of processing techniques, and product quality control.

For example, in automotive manufacturing, the hardness of components is detected by metal hardness testers to ensure they meet design requirements and quality standards. In the research and development of metal materials, the influence of different compositions and processing techniques on the hardness of the materials is evaluated.