No products were found matching your selection.

Other Related Products

-

ZXQ-2Q automatic metallographic prototype (pneumatic), suitable for small, not easy to hold or irregular metallographic and lithographic specimens, so as to cut the cutting or grinding and polishing, and then metallographic, spectral detection or hardness test. In the process of sample preparation, the machine through the program control, its automatic heating, pressure, automatic cooling to automatic pressure discharge stop a series of actions, to achieve the mechanism sample can be unattended effect, reflecting the machine more humanized, simple operation, superb efficiency of the superior characteristics.

-

This grinding machine is suitable for pre-grinding, grinding and polishing of metallographic specimens. It is an essential device for users to make metallographic samples. This machine has a cooling device to cool the specimen during pregrinding to prevent damage to the specimen from overheating. The left plate of the machine is grinding plate, the right disc is throwing disc, can be two people at the same time, easy to use, stable and reliable.

-

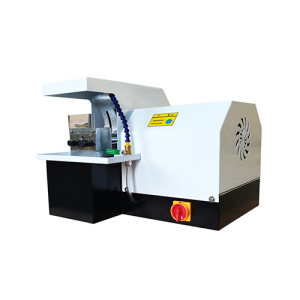

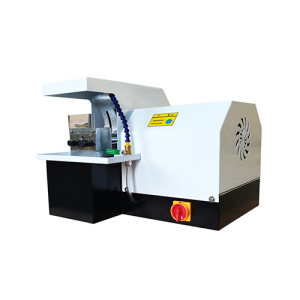

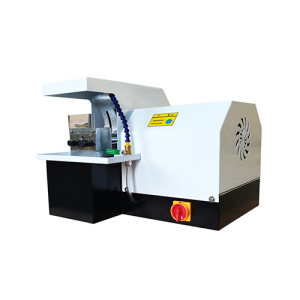

Q-2A metallographic sample cutting machine is a high-speed rotating sheet grinding wheel to intercept metallographic sample, which is widely used in metallographic laboratory cutting of various metal materials.

-

This machine is used for grinding before throwing, for small, not easy to hold or irregular metallographic, rock phase sample inlay. After the inlay, it is easy to grind the sample. It is also beneficial to view the material organization under a gold microscope; test the hardness on the hardness meter.

-

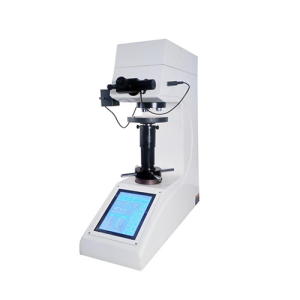

The HBRVD-187.5 Motorized Brinell, Rockwell, and Vickers Hardness Tester features a novel appearance, comprehensive functionality, convenient operation, clear and intuitive display, and stable performance. It is capable of conducting Brinell, Rockwell, and Vickers hardness tests with multiple test forces to meet various hardness testing requirements. This product offers high testing accuracy, simple operation, high sensitivity, and stable readings.

-

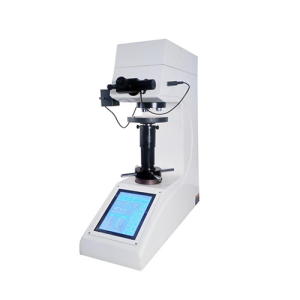

The HBRVS-187.5 Digital Brinell, Rockwell, and Vickers Hardness Tester features a novel appearance, comprehensive functionality, easy operation, clear and intuitive display, and stable performance. It integrates optics, machinery, and electronics as a high-tech product. Capable of conducting Brinell, Rockwell, and Vickers hardness tests with multiple test forces to meet various hardness testing requirements, it offers high testing accuracy, simple operation, high sensitivity, and stable readings. Equipped with a built-in printer, it can also be optionally connected to a computer via an RS232 data cable to export measurement reports.

-

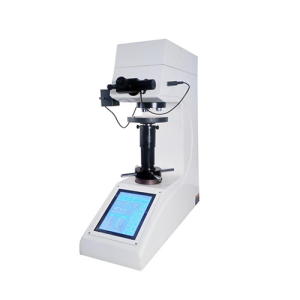

Touch Screen Digital Rockwell Hardness Tester uses an 8-inch touch screen and a high-speed ARM processor, providing intuitive display, user-friendly human-machine interaction, and easy operation. It features fast computing speed, extensive database storage, automatic data correction, and provides data trend line reports.

-

The HBS-62.5AT Touch Screen Digital Automatic Turret Low Load Brinell Hardness Tester utilizes an 8-inch touch screen and a high-speed ARM processor, offering intuitive display, user-friendly human-machine interaction, and simple operation. With fast computation speeds, extensive database storage, automatic data correction, and data trend report capabilities.

-

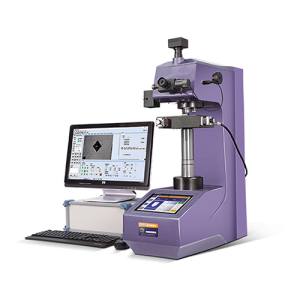

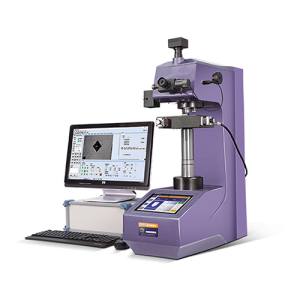

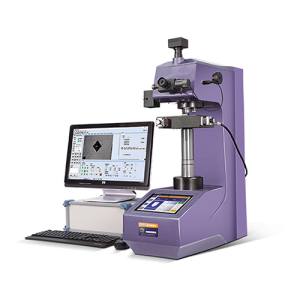

- Automatic loading, retention and unloading

- Autofocus, automatic measurement

- Workbench XYZ axis is fully automatic operation

- With a panoramic scanning function

- 17 kinds of path planning, free setting