The DTQ-600 Low-speed Precision Cutting Machine

This cutting machine is suitable for accurate cutting of thin, small and light special materials with diameter less than 20mm, especially for cutting high value brittle intraocular lens.

This cutting machine is suitable for accurate cutting of thin, small and light special materials with diameter less than 20mm, especially for cutting high value brittle intraocular lens.

The Touch Screen Digital Rockwell Hardness Tester utilizes an 8-inch touch screen and a high-speed ARM processor, providing intuitive display, user-friendly human-machine interaction, and easy operation. It offers fast computing speed, extensive database storage, automatic data correction, and provides data trend line reports.

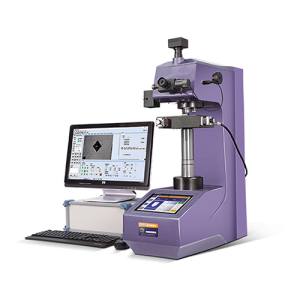

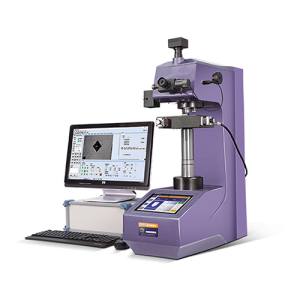

The HVS-1000AT Touch Screen Digital Automatic Turret Micro Vickers Hardness Tester features an 8-inch touch screen and a high-speed ARM processor, providing intuitive display, user-friendly human-computer interaction, and easy operation. It offers fast processing speed, massive database storage, automatic data correction, and provides data line chart reports.

The Touch Screen Digital Rockwell Hardness Tester utilizes an 8-inch touch screen and a high-speed ARM processor, providing an intuitive display, user-friendly human-machine interaction, and easy operation. It boasts fast computing speed, extensive database storage, automatic data correction, and provides data trend line charts.

The HBRVS-187.5F touch screen digital brinell, rockwell, and vickers hardness tester (load cell type) features a novel appearance, comprehensive functionality, easy operation, clear and intuitive display, and stable performance. It is capable of conducting Brinell, Rockwell, and Vickers three kinds of hardness tests with multiple test forces to meet various hardness testing requirements. It boasts high testing accuracy, simple operation, high sensitivity, and stable readings.

This mill is a desktop double-disc double-control grinding machine, suitable for rough grinding, fine grinding and polishing of gold test samples.