No products were found matching your selection.

Other Related Products

-

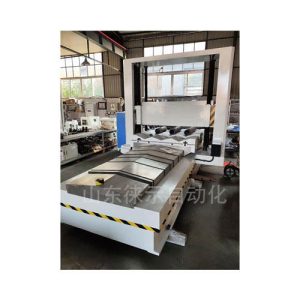

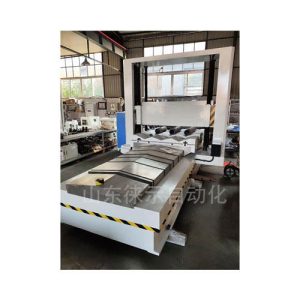

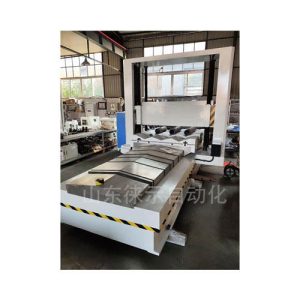

ZXQ-2Q automatic metallographic prototype (pneumatic), suitable for small, not easy to hold or irregular metallographic and lithographic specimens, so as to cut the cutting or grinding and polishing, and then metallographic, spectral detection or hardness test. In the process of sample preparation, the machine through the program control, its automatic heating, pressure, automatic cooling to automatic pressure discharge stop a series of actions, to achieve the mechanism sample can be unattended effect, reflecting the machine more humanized, simple operation, superb efficiency of the superior characteristics.

-

- Automatic control operation of touch screen

- With a cooling device, rapid cooling

- 6 minutes to get fast

- 4 test samples can be inlaid at one time

- High safety coefficient, stable performance, and high sample preparation efficiency

-

The HVS-1000AT Touch Screen Digital Automatic Turret Micro Vickers Hardness Tester features an 8-inch touch screen and a high-speed ARM processor, providing intuitive display, user-friendly human-computer interaction, and easy operation. It offers fast processing speed, massive database storage, automatic data correction, and provides data line chart reports.

-

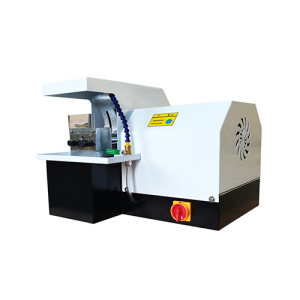

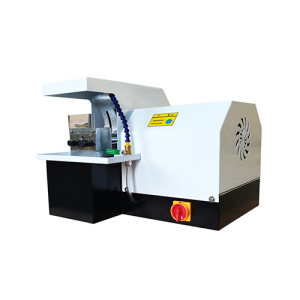

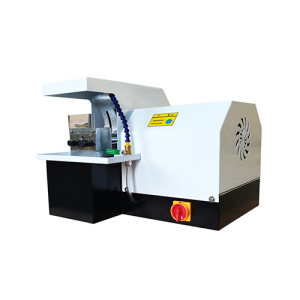

Q-2A metallographic sample cutting machine is a high-speed rotating sheet grinding wheel to intercept metallographic sample, which is widely used in metallographic laboratory cutting of various metal materials.

-

The Touch Screen Digital Rockwell Hardness Tester utilizes an 8-inch touch screen and a high-speed ARM processor, providing intuitive display, user-friendly human-machine interaction, and easy operation. It offers fast computing speed, extensive database storage, automatic data correction, and provides data trend line reports.

-

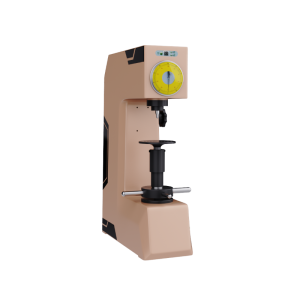

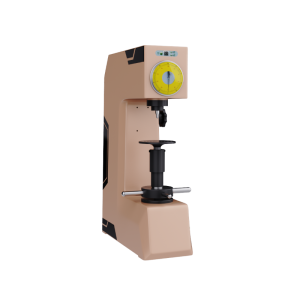

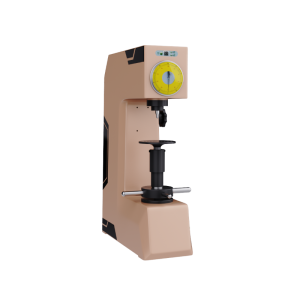

This hardness tester adopts advanced design concepts. Advanced technologies in mechanical, electrical, and optical aspects are employed in the field of hardness testers today. The test results are precise, with strong repeatability. Equipped with Brinell hardness image processing system, it offers high automation, low labor intensity for operators, minimal human error, and a novel and appealing appearance. It is one of the most advanced Brinell hardness testers domestically and can fully replace similar imported products. It can quickly and accurately measure the Brinell hardness value of the test piece.

-

The HBRVS-187.5F touch screen digital brinell, rockwell, and vickers hardness tester (load cell type) features a novel appearance, comprehensive functionality, easy operation, clear and intuitive display, and stable performance. It is capable of conducting Brinell, Rockwell, and Vickers three kinds of hardness tests with multiple test forces to meet various hardness testing requirements. It boasts high testing accuracy, simple operation, high sensitivity, and stable readings.

-

The new model HRD-150 electric Rockwell Hardness Tester is controlled by a motor for the loading, holding, and unloading of test force, with the option to select a hold time. It offers convenient, rapid operation without human error, and demonstrates high sensitivity and stability.

-

HV(S)-5/10/30/50(A)T Touchscreen (Digital) (Automatic Turret) Vickers Hardness Tester utilizes an 8-inch touchscreen and high-speed ARM processor, offering an intuitive display, user-friendly interaction, and straightforward operation. It provides fast computation speed, massive database storage, automatic data correction, and offers data trend line reports.